Influence of resin-nanoceramic CAD/CAM block shade and thickness on the microhardness of dual-cured resin cement

Abstract

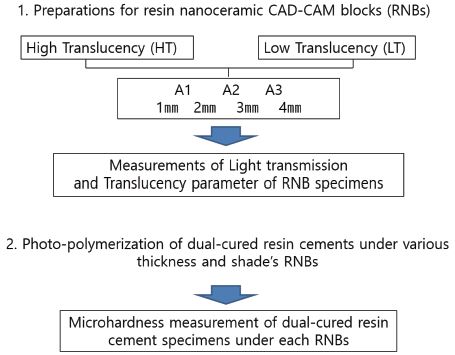

The purpose of this study was to examine the effect of shade and thickness of resin-nanoceramic CAD-CAM block (RNB) on the microhardness of dual-cured resin cement, as well as to measure the number of photons transmitted through RNBs of different thicknesses and colors. One dual-cured resin cement was used to prepare resin cement specimens. Resin cement specimens were light-cured for 40 seconds through 3 shades (A1, A2, A3 in HT (high translucency) and LT (low translucency) respectively) and four thicknesses (1, 2, 3, 4 mm) of RNB specimens. Vickers microhardness measurements of resin cement specimens were performed using a Vickers hardness tester. The light transmission of RNB specimens was measured using a spectrometer (SpectroPro-500, Acton Research, Acton, MA, U.S.A.), and the translucency parameter was calculated using the CIEL*a*b* system. Data were statistically analyzed by ANOVA and Tukeyʼs test. There was a significant decrease of microhardness of resin cement specimen with an overlay of 4 mm of RNB thickness and A3 shade in comparison to A1 and 1 mm, respectively (p<0.05). The translucency parameter values and light transmission of RNBs tested differed significantly, according to the thicknesses of the specimen (p<0.05). Light transmission is decreased with increase in the thicknesses of RNBs. Shade A1 transmitted more light than darker blocks. A decrease in microhardness of resin cement specimens was observed with increasing thickness and shade (A1 to A3) of RNBs.

초록

본 연구에서는 다양한 두께와 색조를 가진 레진 –나노세라믹 CAD-CAM block(RNB)의 시편을 이용하여 광중합 시 시편을 투과하는 광자의 수와 시편을 통과하는 빛의 양에 영향을 미칠 수 있는 반투명도 지수를 측정하고, 시편 하방의 이원중합 레진시멘트의 미세경도 측정을 통해 그 중합적 특성을 파악하였다. Lava Ultimate (3M/ESPE, St. Paul, MN, USA) 세라믹 시편을 A1, A2, A3색조 (HT (high translucency)와 LT (low translucency))로 각각 1, 2, 3, 4 mm 두께로 제작하였다 (n = 3). Photodiode detector (M1420, EG&G PARC, Princeton, NJ, U.S.A.)를 통해 시편을 통과하는 광자의 수를 측정하였고 spectrophotometer (SpectroPro-500, Acton Research, Acton, MA, U.S.A.)를 이용하여 시편의 반투명도 지수를 측정하였다. Stainless steel mold (6 mm 직경, 1 mm 두께)를 제작하여 이원중합 레진시멘트 (Rely X ARC, 3M/ESPE, St. Paul, MN, USA)를 제조사의 지시대로 조작하여 적용 후 Mylar strip를 얹은 뒤 주입된 레진시멘트가 완전히 덮일 수 있도록 각 실험군의 시편을 위치시키고 광조사기로 40초간 광중합 하였다. 이후 24시간 동안 37°C에 보관 후 미세경도를 측정하였다.

광자의 수는 HT, LT군에서 모두 세라믹 시편의 두께가 증가함에 따라 유의하게 감소하였고, A1 군이 A2군과 A3군에 비해 유의하게 적은 감소를 보였다 (p<0.05). 반투명도 지수는 HT, LT 그룹에서 시편의 두께가 증가함에 따라 유의하게 감소하였고 A1군이 A2군과 A3군에 비해 높은 값을 나타냈다 (p<0.05). HT, LT그룹 각각 두께가 증가함에 따라, 색조가 증가함에 따라 미세경도는 감소하였으며, 1 mm군과 4 mm군, 그리고 A1군과 A3군에서는 통계적으로 유의하게 감소하였다 (p<0.05).

Keywords:

Resin-nanoceramic CAD/CAM blocks, Dual-cured resin cement, Microhardness키워드:

레진-나노세라믹 CAD-CAM 블록, 이원중합레진세멘트, 미세경도Ⅰ. INTRODUCTION

Currently, with the continuous development of indirect restoration and cementation materials, CAD-CAM restorations are becoming increasingly popular in the field of esthetic dentistry. Luting materials are an important factor in the longevity of dental restorative materials. The clinical success of CAD/CAM esthetic restorations can be determined by the strength and durability of the adhesion between the tooth surface, cement material, and restorative material. Therefore, resin cements are used most commonly in the cementation of esthetic restorations because of their excellent shade-matching and mechanical properties, such as highly flexural strength and compressive strength. Resin cements can be classified as either chemical-cure type, light-cure type or dual-cure type, depending on their polymerization strategy. Chemical-cured resin cement requires a long setting time and has an uncontrolled working time. In contrast, light-cured resin cement allows easier manipulation, but the thickness of the ceramics and the tooth structure can be adversely affected by any incomplete polymerization of the cement layer. This is because the light transmittance through the restoration material decreases with increasing ceramic thickness, which can lead to clinical failure between restoration and tooth structure. Dual-cured resin cement possesses the advantage of both chemical- and light-cure materials (Lee & Um, 2001; Santos et al., 2004; Jongsma et al., 2012). Dual-cured resin cement contains the peroxide-amine components found in chemical-cure systems, in addition to the photo initiator, camphorquinone (CQ), used in light-cure materials. Therefore, light polymerization of dual-cured resin cement allows better control during the cementation procedure, and the chemical polymerization of dual-cured resin cement can be hardened in deep areas, where curing light cannot reach (Uctasli et at, 1994). Although the materials are dual-cured, an adequate quantity of light is needed to initiate t he polymerization process (Kilinc et al., 2011). Generally, the factors that affect resin cement polymerization are restoration thickness, restoration shade, translucency, and resin cement polymerization type (Cardash et al., 1993; Tanoue et al., 2003; Lee et al., 2008). The composition, fillers, opacity, and shade of the ceramic material can attenuate light from the curing unit, which can affect the polymerization of the resin cement under a ceramic restoration (Chan & Boyer, 1989; Rasetto et al., 2004; Archegas et al., 2012; AlShaafi et al., 2014; Lauvahutanon et al., 2014).

Currently, a range of CAD/CAM blocks are available for esthetic dental restorations, which include feldspathic glass ceramics, leucite-reinforced glass ceramics, lithium disilicate glass ceramics, yttrium tetragonal zirconia polycrystals, and composite resin (Awada & Nathanson, 2015). Traditional ceramic blocks can produce esthetic restorations achieving the advantageous properties of ceramics, such as durability, surface polish, and color stability (Zahran et al., 2008; Kois et al., 2013; Quinn et al., 2014) On the other hand, some studies have reported a higher incidence of failure of these materials due to the brittle characteristics of the ceramics (Attia et al., 2006; Coldea et al., 2013; Kois et al., 2013). Therefore, manufacturers have been developing ceramic and resin composite combined blocks to improve flexural properties. Among them, Lava Ultimate (LVU; 3M ESPE, St. Paul, MN, U.S.A.) blocks that made of nanoceramic particles embedded in a highly polymerized resin matrix (Schlichting et al., 2011; Koller et al., 2012; Kois et al., 2013) are popular resin-nanoceramic CAD/CAM materials to the clinicians. Nanofiller particles can improve their translucency because of particles with a diameter smaller than the wavelength of visible light cause less light scattering and absorbance. They also have different translucency and shade, which can affect the attenuation of light that passes through the restorative material. In a cementation procedure using dual-cured resin cement, the shade and thickness of the restoration may vary considerably. The durable bond between the CAD/CAM block and the tooth for a successful restoration is dependent on achieving adequate polymerization of the resin cement.

The purpose of this study was to assess the microhardness of dual-cured resin cement that was overlaid with LVU blocks of different shades and thicknesses. Through the study, translucency parameter (TP) of LVU blocks and the number of photons transmitted through the blocks were measured to evaluate their effect on the microhardness of dual-cured resin cement.

Ⅱ. MATERIALS AND METHODS

1. Resin-nanoceramic CAD-CAM blocks (RNBs)

For this study, six LVU blocks with different shades and one dual-cured resin cement (Rely X ARC; 3M/ESPE, St. Paul, MN, U.S.A.) were used. Table 1 lists their compositions.

To simulate indirect restoration, LVU blocks with thicknesses of 1 mm, 2 mm, 3 mm, and 4 mm were made with HT (high translucency) and LT (low translucency) in shades of A1, A2, and A3 (n=3). Digital calipers were used to confirm the thickness of each block.

2. Light transmission

When light emitted from an LED curing unit is passed into the LVU blocks, it will be attenuated. To determine how the light attenuates within the block, the number of photons transmitted through blocks of different thicknesses and shades was measured using a photodiode detector (M1420, EG&G PARC, Princeton, NJ, U.S.A.) and spectrometer (SpectroPro-500, Acton Research, Acton, MA, U.S.A.). The LVU blocks were placed on a plate, which had a 6.8-mm diameter hole. The photodiode detector was placed under this hole in a fixed position for the measurements. The end of the light tip was placed in contact with the top of the block specimens, and the curing light was then irradiated and measured.

3. Translucency parameter

A spectrophotometer (CM-3600d, Konica Minolta, Osaka, Japan) was utilized to measure the color of the LVU blocks. The color was measured by placing the specimen at the center of the target mask (specimen stage) in reflectance (%R) mode with white and black backgrounds. This target mask had a 6-mm hole at the center. This hole enabled consistency in specimen placement during the measurements. From the measured reflectance data, the CIEL*a*b* color values were evaluated using the internal software of the measurement system. The TP values were determined by calculating the color difference between the readings over a black and white background for the same specimen using the following equation:

TP = [(L*B-L*W)2+(a*B-a*W)2+(b*B-b*W)2]1/2,

where subscripts B and W refer to the color coordinates over the black and white background, respectively.

4. Microhardness

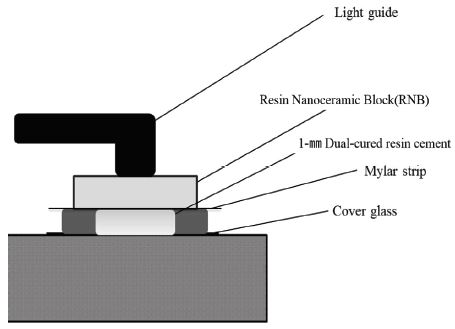

A dual-cured resin cement was used in this experiment. Twenty-four experimental groups (6 shades×4 thickness), and a total of 72 resin cement specimens were evaluated. A stainless steel mold (6 mm in diameter, 1 mm in thickness) was placed on a glass slide with black paper to reduce the light reflectance from the table surface onto the specimen. We controlled for the thickness of the dual-cured resin cement using a 1-mm thick stainless steel mold. The dual-cured resin cement was manipulated in a separate mixing pad and inserted into the mold cavity using a plastic instrument according to the manufacturer’s instructions. A Mylar strip was positioned over the resin cement to ensure an even and smooth surface, and to isolate it from the RNB. Light-curing was performed through a RNB for 40 s using an LED curing unit (BluephaseⓇ 20i, Ivoclar-Vivadent, Schaan, Liechtenstein) with an intensity of 1400 mW/cm2 (Figure 2). All specimens were stored in distilled water at 37°C for 24 h to allow delayed polymerization to occur before testing.

Polymerization of resin cement through the resin nanoceramic block (RNB).(RNBs with thicknesses of 1 mm, 2 mm, 3 mm, and 4 mm were made with HT (high translucency) and LT (low translucency) in shades of A1, A2, and A3)

Vickers microhardness measurements were taken from the top surfaces of each resin cement sample from three different locations using a Vickers hardness tester (MVK-H1; Akashi Co., Tokyo, Japan) with a 200-gf load and a 15-s dwell time after 24 h. Three indentations were made for each specimen (three specimens for each twenty-four groups).

5. Statistical analysis

Statistical analysis was performed using statistical software (SPSS 18.0, SPSS Inc., Chicago, IL, U.S.A.). The acquired data for the translucency parameter (TP), photon count and microhardness were analyzed using two-way ANOVA, followed by a Post-hoc Tukey’s test for multiple-comparisons, if necessary. A student t-test was used to compare the microhardness of the resin cement specimens in the HT and LT groups. Statistical significance was set to p<0.05 for all tests.

Ⅲ. RESULTS

1. Light transmission

Table 2 lists the change in the photon counts detected in the subsurface of the RNB. In light transmission, the number of photons decreased with increasing thickness of the RNBs, and the lowest attenuation coefficient was observed in the A1 shade of the HT group.

2. Translucency parameter (TP)

Table 3 presents the TP of RNBs tested at different shades and thicknesses. The TP values in thinner RNB specimens were significantly higher than thicker RNB specimens. In terms of shade, A1 was significantly higher than A2 and A3. No significant differences were observed between A2 and A3 in both HT and LT groups.

3. Microhardness

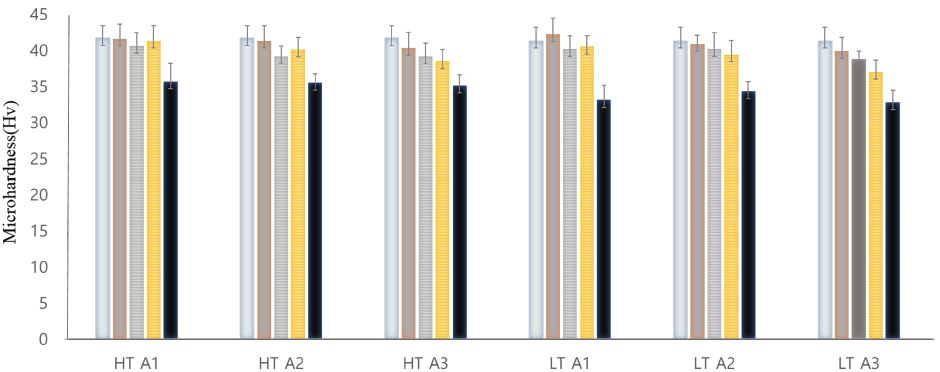

Table 4 and figure 3 shows the microhardness of the resin cement specimens at the top of the surface. The microhardness of the HT group ranged from 35.1 to 41.6 Hv on the top surface, and the LT group ranged from 28.7 to 42.2 Hv on the top surfaces. Numerical reduction of microhardness was observed in the HT and LT groups with increasing thickness from shade A1 to A3 of the RNB specimens. A statistically significant difference was observed between A1 and A3, as well as between 1 mm and 4 mm, respectively. No significant differences were observed between 2 mm and 3 mm in the HT and LT groups on top surfaces. In addition, there were no significant differences between A2 and A1, A3 in the HT group, as well as between A2 and A1 in the LT group on top surfaces.

Ⅳ. DISCUSSION

The study and specimen setup were designed in close simulation of a clinical cementation procedure for indirect restorations using RNBs and dual-cured resin cement. LVU is a RNB indicated for indirect restorations that contains nanoceramic particles embedded in a highly-polymerized resin matrix. Currently, dual-cured resin cements are the most commonly used dental materials for luting esthetic restoration. In this study, we focused on the polymerization characteristic of dual-cured resin cement through RNBs with different shades and thicknesses.

In most clinical cases, indirect restorations of the posterior teeth with inlays or onlays require a thickness of at least 1 mm of buccal and lingual surface and up to 1.5–2 mm on the cusp, and 3–4 mm of proximal box depth is required. To investigate the influence of light transmittance on the physical properties of dual-cured resin cement underlying such indirect restorations, the present study used RNB specimens with a prepared thickness of 1, 2, 3, and 4 mm (Tanoue et al., 2003).

In the present study, the number of photons decreased exponentially with increasing specimen thickness (attenuation coefficient, mm-1, from -0.489 to -0.701). This results that decreased exponentially with increasing RNBs’ thickness can be explained by scattering and absorption of the light through the RNB’s specimens. Such an exponential decrease normally follows the Beer-Lambert law (Emami et al., 2005). The number of photons that is related to the intensity of incident light, where a high intensity implies a high quantity of photons regulates the capacity to activate the photoinitiator (Hasegawa et al., 1991; Emami et al., 2005). Also, light scattering and absorption was affected by composition of the materials such as filler type and filler content, matrix, pigments and opacifiers. In this study, among the specimens, A1 HT group showed a slightly lower attenuation coefficient than the other groups, which may be due to the relatively higher translucency and light shade. A lower attenuation coefficient suggests that there are more photons surviving and fewer photons lost in the subsurface. It may expect to activate more effectively the photoinitiator of the light-cured or dual-cured resin cement.

TP indicates the color difference between the block specimens as a consequence of background differences (black and white) and the translucency of the specimens. LVU is regarded as optically heterogeneous materials, which refers to a transparent medium including components of multiple refractive indices that cause light scattering, resulting in affecting to the light transmission (Rueggeberg & Caughman, 1993; Lauvahutanon et al., 2014). Moreover, nanofiller particles can improve their translucency because of particles with a diameter smaller than the wavelength of visible light cause less light scattering and absorbance (Soares et al., 2006). They also have different translucency and shade, which can affect the attenuation of light that passes through the restorative material. The higher TP may allow light to penetrate deeper up to RNB specimens. Moreover, the translucency of RNB depends on the scattering and absorption coefficients of the filler, matrix and pigments as well as their thickness. In the present study, TP decreased significantly with increasing block thickness, regardless of the HT or LT. The translucency of the RNB increases with decreasing thickness, In addition, regarding shades, A1 showed significantly higher TP than A2 and A3 shades. This might be because translucency can be affected with a darker shade, and may influence light penetration (Pereira et al., 2010).

In this study, decreasing tendency of microhardness as the RNB’s thickness increased was observed. Regardless of shade and translucency, the higher microhardness value was obtained in the 1 mm of the specimens and the lower microhardness value in 4 mm of the specimens. In 2 mm and 3 mm of the specimens, the microhardness values were statistically significantly lower than those of specimens with 1 mm thickness. These results indicate that as the thickness of the specimen becomes thicker, the chance of light scattering within the specimen increases, which induces to a decrease in TP and photons. It may in turn lead to a detrimental effect on the photo-polymerization of light-cured or dual-cured resin cements under the specimens. In this study, regarding shades, both the HT and LT groups showed statistically significant differences between A1 and A3 were observed. No significant differences were observed between A1 and A2 in both HT and LT groups. If shades with a higher chroma are used in an indirect restoration, the pigments of the restoration absorb a significant amount of light and the inversely transmitted light is decreased, which may adversely affect the curing of underlying resin cements (Soares et al., 2006). This is because the light transmittance through each specimens decreases with increasing thickness and shade of specimens. Attenuated light can affect the polymerization of the dual-cured resin cement under the specimens. It means that clinicians should be cautious about thickness and shade when restoring deep cavity.

The polymerization reaction of dual-cured resin cements consists of two mechanisms: a light-cured process initiated by camphorquinone, and additional chemical polymerization (Lee & Um, 2001; Santos et al., 2004; Kilinc et al., 2011). Despite their independent onset, these two polymerization modes possess dynamic free radical formation and monomer conversion, overlapping each other during the curing process. In this study, the microhardness test results showed that there were no significant differences between A2 and A1, A3 in the HT group, and no significant differences were observed between A1 and A2 in the LT group (p>0.05). Throughout the assessment of the effects of RNB thickness, there were no significant differences between the 2 mm and 3 mm RNB specimens in both the HT and LT groups (p>0.05). This may be due to the chemical-curing component of the dual-cured resin cement that compensates for the greater light transmission attenuation with increasing RNB thickness.

In our experiment, the difference of the thickness and shade of the RNB affects the properties of the resin cement layer. This is because the transmittance of the light passing through RNB is changed, which affects the polymerization of the dual-cured resin cement and eventually changes the microhardness, which is one of the physical properties of the dual-cured resin cement. For photo-activated or dual-cured resin cements, satisfactory mechanical properties can be achieved when light penetrates deeply enough to the bottom of the restoration to activate the light activation component and photo initiators. On the other hand, an increased thickness of the indirect restoration or darker shade exhibits a reduction in light penetration, which leads to unfavorable photoactivation. The purpose of this study was to investigate the effect of color and thickness of RNB, which is a popular material used in the treatment of esthetic restorations, on microhardness of dual-cured resin cement under restorations when irradiated with light. However, due to the polymeric nature of the resin cement, the microhardness value in this experiment contains the result of chemical polymerization, which has limitations in showing only photo-polymerization properties. In future studies, additional physical properties studies should be continued according to the polymerization method of dual-cured resin cement under various new esthetic restorative materials.

Ⅴ. CONCLUSIONS

Within the limitations of the present study,

- 1. In light transmission, the number of photons decreased exponentially with increasing thickness of RNDs, and the lowest attenuation coefficient was observed in the shade A1 of the HT group.

- 2. TP decreased significantly with increasing thickness of the disks (p<0.001). In shade, A1 was significantly higher than A2 and A3 (p<0.001).

- 3. A decrease in microhardness was observed in the HT and LT groups with increasing thickness and shade (A1-A3) of RNDs, regardless of top and bottom of the resin specimens. A significant difference was observed between A1 and A3 as well as between 1 mm and 4 mm (p<0.001). Different shades and thicknesses of RNBs influence microhardness of dual-cured resin cements.

Therefore, clinicians will need to cement the restorations using LVU RNB in consideration of the effects of these shades and thicknesses on bonding when needed deep depths of dark shade for aesthetic restoration.

Acknowledgments

* This work was supported by a 2-Year Research Grant of Pusan National University.

References

- AlShaafi, MM, AlQahtani, MQ, Price, RB, (2014), Effect of exposure time on the polymerization of resin cement through ceramic, J Adhes, 16, p129-135.

-

Archegas, LR, de Menezes Caldas, DB, Rached, rN, Soares, P, Souza, EM, (2012), Effect of ceramic veneer opacity and exposure time on the polymerization efficiency of resin cements, Oper Dent, 37, p281-289.

[https://doi.org/10.2341/11-134-l]

-

Attia, A, Abdelaziz, KM, Freitag, S, Kern, M, (2006), Fracture load of composite resin and feldspathic all-ceramic CAD/CAM crowns, J Prosthet Dent, 95, p117-123.

[https://doi.org/10.1016/j.prosdent.2005.11.014]

-

Awada, A, Nathanson, D, (2015), Mechanical properties of resin-ceramic CAD/CAM restorative materials, J Prosthet Dent, 114, p587-593.

[https://doi.org/10.1016/j.prosdent.2015.04.016]

-

Cardash, HS, Baharav, H, Pilo, R, Ben-Amar, A, (1993), The effect of porcelain color on the hardness of luting composite resin cement, J Prosthet Dent, 69, p620-623.

[https://doi.org/10.1016/0022-3913(93)90293-w]

-

Chan, KC, Boyer, DB, (1989), Curing light-activated composite cement through porcelain, J Dent Res, 68, p476-480.

[https://doi.org/10.1177/00220345890680030801]

-

Coldea, A, Swain, MV, Thiel, N, (2013), Mechanical properties of polymer-infiltrated ceramic network materials, Dent Mater, 29, p419-426.

[https://doi.org/10.1016/j.dental.2013.01.002]

-

Emami, N1, Sjödahl, M, Söderholm, KJ, (2005), How filler properties, filler fraction, sample thickness and light source affect light attenuation in particulate filled resin composites, Dent Mater, 21, p721-730.

[https://doi.org/10.1016/j.dental.2005.01.002]

-

Hasegawa, EA, Boyer, DB, Chan, DC, (1991), Hardening of dual-cured cements under composite resin inlays, J Prosthet Dent, 66, p187-192.

[https://doi.org/10.1016/s0022-3913(05)80046-0]

-

Jongsma, LA, Kleverlaan, CJ, Pallav, P, Feilzer, AJ, (2012), Influence of polymerization mode and C-factor on cohesive strength of dual-cured resin cements, Dent Mater, 28, p722-728.

[https://doi.org/10.1016/j.dental.2012.03.002]

-

Kilinc, E, Antonson, SA, Hardigan, PC, Kesercioglu, A, (2011), The effect of ceramic restoration Shade and thickness on the polymerization of light- and dual-cure resin cements, Oper Dent, 36, p661-669.

[https://doi.org/10.2341/10-206-l]

-

Kois, DE, Isvilanonda, V, Chaiyabutr, Y, Kois, JC, (2013), Evaluation of fracture resistance and failure risks of posterior partial coverage restorations, J Esthet Restor Dent, 25, p110-122.

[https://doi.org/10.1111/jerd.12018]

- Koller, M, Arnetzl, GV, Holly, L, Arnetzl, G, (2012), Lava ultimate resin nano ceramic for CAD/ CAM: customization case study, Int J Comput Dent, 15, p159-164.

-

Lauvahutanon, S, Takahashi, H, Shiozawa, M, Iwasaki, N, Asakawa, Y, Oki, M, Finger, WJ, Arksornnukit, M, (2014), Mechanical properties of composite resin blocks for CAD/CAM, Dent Mater, 33, p705-710.

[https://doi.org/10.4012/dmj.2014-208]

-

Lee, IB, Um, CM, (2001), Thermal analysis on the cure speed of dual cured resin cements under porcelain inlays, J Oral Rehabil, 28, p186-197.

[https://doi.org/10.1046/j.1365-2842.2001.00639.x]

-

Lee, IB, An, W, Chang, J, Um, CM, (2008), Influence of ceramic thickness and curing mode on the polymerization shrinkage kinetics of dual-cured resin cements, Dent Mater, 24, p1141-1147.

[https://doi.org/10.1016/j.dental.2008.03.015]

-

Pereira, SG, Fulgêncio, R, Nunes, TG, Toledano, M, Osorio, R, Carvalho, RM, (2010), Effect of curing protocol on the polymerization of dual-cured resin cements, Dent Mater, 26, p710-718.

[https://doi.org/10.1016/j.dental.2010.03.016]

-

Quinn, GD, Giuseppetti, AA, Hoffman, KH, (2014), Chipping fracture resistance of dental CAD/CAM restorative materials: part I-procedures and results, Dent Mater, 30, pe99-111.

[https://doi.org/10.1016/j.dental.2014.02.010]

-

Rasetto, FH, Driscoll, CF, Prestipino, V, Masri, R, von Fraunhofer, JA, (2004), Light transmission through all-ceramic dental materials: a pilot study, J Prosthet Dent, 91, p441-446.

[https://doi.org/10.1016/s0022-3913(04)00110-6]

- Rueggeberg, FA, Caughman, WF, (1993), The influence of light exposure on polymerization of dual-cure resin cements, Oper Dent, 18, p48-55.

- Santos, GC Jr, El-Mowafy OM, Rubo, JH, Santos, MJ, (2004), Hardening of dual-cure resin cements and a resin composite restorative cured with QTH and LED curing units, J Can Dent Assoc, 70, p323-328.

-

Schlichting, LH, Maia, HP, Baratieri, LN, Magne, P, (2011), Novel-design ultra-thin CAD/CAM composite resin and ceramic occlusal veneers for the treatment of severe dental erosion, J Prosthet Dent, 105, p217-226.

[https://doi.org/10.1016/s0022-3913(11)60035-8]

-

Soares, CJ, da Silva NR, Fonseca, RB, (2006), Influence of the feldspathic ceramic thickness and shade on the microhardness of dual resin cement, Oper Dent, 31, p384-389.

[https://doi.org/10.2341/05-51]

-

Tanoue, N, Koishi, Y, Atsuta, M, Matsumura, H, (2003), Properties of dual-curable luting composites polymerized with single and dual curing modes, J Oral Rehabil, 30, p1015-1021.

[https://doi.org/10.1046/j.1365-2842.2003.01074.x]

-

Uctasli, S, Hasanreisoglu, U, Wilson, HJ, (1994), The attenuation of radiation by porcelain and its effect on polymerization of resin cements, J Oral Rehabil, 21, p565-575.

[https://doi.org/10.1111/j.1365-2842.1994.tb01171.x]

-

Zahran, M, El-Mowafy, O, Tam, L, Watson, PA, Finer, Y, (2008), Fracture strength and fatigue resistance of all-ceramic molar crowns manufactured with CAD/CAM technology, J Prosthodont, 17, p370-377.

[https://doi.org/10.1111/j.1532-849x.2008.00305.x]