The effect of titanium nitride coating on the fatigue fracture resistance of rotary nickel titanium instruments

The purpose of this study was to examine the effect of titanium nitride coating treatment on the cyclic fatigue resistance of two nickel-titanium rotary instruments and to examine the coated surface under a scanning electron microscope (SEM). A total of 48 Nickel-titanium files from two brands (K3, SybronEndo, Orange, CA, #25/.06 taper; Helix, Diadent, Daegu, Korea, #30/.06taper) were tested. The experimental group (12 files from each brand was treated with titanium nitride through physical vapor deposition method. No treatment was done to the control group. A Endo Tester (Denbotix, Bucheon, Gyeonggi-do Korea) that simulated actual canal configuration and pecking motion of files allowed the instruments to rotate freely inside and move up and down along the artificial canal. The time it took for the file to fracture was recorded and was multiplied by the revolution per minute to obtain the number of cycles to failure (NCF). SPSS statistical package was used to analyze the results with Mann-Whitney U test. Four files, randomly selected from each group, were examined using under a SEM to examine the surface characteristics. NCF of K3 files coated with titanium nitride decreased significantly. Helix files showed no difference between the experimental and control groups. The presences of titanium nitride coating were observed under SEM. Titanium nitride treatment didn’t significantly improve the fatigue fracture resistance in NiTi rotary files.

Keywords:

니켈-티타늄 전동파일, 질화티타늄 물리증착법, 표면처리, 피로파절, 피로파절저항성INTRODUCTION

In modern endodontics, rotary nickel titanium (NiTi) instruments are widely used because of their superb characteristics such as shape memory, superelasticity, high flexibility, fatigue resistance, biocompatibility, and corrosion resistance. However, NiTi instruments suffer increased cyclic fatigue, which leads to instrument fracture when used repeatedly. Such fatigue fracture occurs without any warning, with reported incidence as high as 5% (Sattapan et al., 2000; Parashos et al., 2004; Parashos and Messer, 2006).

The factors that influence rotary NiTi instrument fractures include instrument design, manufacturing process, sequence and protocols of instrument use, root canal morphology, and duration of instrument use. Factors of instrument design, which influence fracture resistance, include cross-sectional design, diameter, and taper. For example, as the diameter and the cross-sectional area increases, the instrument becomes more prone to cyclic failure (Haikel et al., 1999). Inappropriate and excessive instrument use also causes instrument fracture (Sattapan et al., 2000). As the rotational speed is increased, the number of cycles to failure (NCF) decreases, but light apical pressure and in-and-out movements reduce the fracture incidence (Li et al., 2002). In addition, the canal morphology affects instrument fractures; as the radius of curvature decreases and the curvature angle increases, the NCF decreases (Li et al., 2002; Zelada et al., 2002).

Manufacturing defects are also well-known causes of instrument factures (Anderson et al., 2007; Madarati et al., 2008). NiTi instruments contain a small amount of oxygen, nitrogen, carbon, and hydrogen. Cracks propagate along their borders (Alapati et al., 2003). Irregular surfaces left during the manufacturing process act as the point of stress concentration. The grinding process of natural grain during instrument manufacturing also weakens the mechanical structure by creating manufacturing defects (Tripi et al., 2006; Yao et al., 2006). Therefore many surface treatment methods are being developed to reduce surface defects and rotary NiTi instrument fracture. Most commonly used methods include ion implantation(Schafer, 2002; Tripi et al., 2003) and electropolishing (Anderson et al., 2007).

Titanium nitride (TiN) is an exceptionally strong ceramic material, and it is coated on titanium composite metal, steel, carbide, and aluminum components to improve surface characteristics. TiN coatings improve the abrasion and corrosion resistance. They are also non-toxic (PalDey and Deevi, 2003). To create TiN coatings with a thin film thicknesses, physical vapor deposition and chemical vapor deposition methods are used. Pure sublimated titanium and high-energy nitrogen in vacuum react with one another in both methods (Matthews, 1985).

The purpose of this study was to examine the effect of a TiN coating treatment on the cyclic fatigue resistance of two nickel-titanium rotary instruments. The coated surfaces were examined under a scanning electron microscope.

MATERIALS AND METHODS

NiTi instrument system and surface treatment

Two NiTi instruments were used for this study: K3 files (SybronEndo, Orange, CA, 25mm, #25/.06taper) and Helix files (Diadent, Daegu, Korea, 25mm, #30/.06taper). Twenty-four instruments of each NiTi instrument type were used. Twelve instruments were surface-treated while the others were left untreated as controls. In the experimental group, a physical vapor deposition method was used to coat the surface with sublimated TiN film. Vacuum arc ion plating, which has a superb degree of ionization and adhesion of coating, was used. TiN coating was done at minimum temperature and high pressure to avoid instrument distortion (Boxman and Goldsmith, 1989).

NCF (Number of cycles to failure) measurement

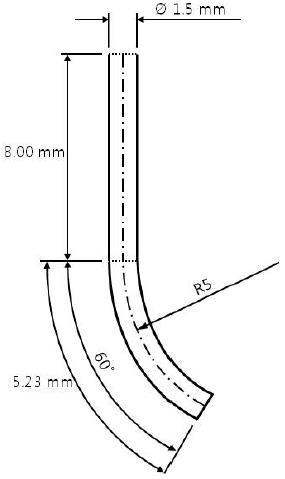

Endo tester (Figure 1, Denbotix, Bucheon, Gyeonggi-do, Korea), which was designed to simulate an actual canal and instrument movement, was used with an electric motor (Aseptico, Woodinville, WA, USA). It simulated the rotational and vertical movements of rotary NiTi instruments, and repeated tensile and compressive stress was placed on the instrument. To simulate the morphology of an actual canal and instrument movement, an artificial canal with the following parameter was designed using two circular metal plates: a straight segment of 8.00 mm with an arc length of 5.23 mm, a curvature radius of 5mm, and the arc at the apical portion of the canal (Figure 2). The pecking motion was set to repeat in one second intervals from 6 mm above the apex to the apex. An electric motor set at 300 rpm and a torque of 130 g-cm was connected to the Endo tester. In order to minimize friction and heat generation on the artificial canal wall, RC-Prep (Premier Dental Produce, Norristown, PA, USA) was applied to each instrument before use. The instrument fracture was detected by sound. The time to fracture was recorded in seconds.

Endo tester (A), Artificial root canal (B), Electric torque-controlled motor (C), and Endo tester after a file was mounted on an electric torque-controlled motor (D).

Statistical analysis

By multiplying the recorded time by the rotational speed, the NCF was calculated. Due to the small number of samples, normal distribution could not be assumed, and Mann-Whitney analysis, a non-parametric test was used for comparison at α=0.05 level using SPSS (Statistical Product and Service Solutions, IBM, New York, USA).

Scanning Electron Microscope (SEM) Evaluation

After the instruments fractured, from the Helix and K3 nickel file groups, one untreated instrument and one TiN treated instrument were examined under a scanning electron microscope (FE-SEM; S-4700, Hitachi, Tokyo, Japan) to analyze the lateral surface.

RESULTS

NCF measurement and comparison of fatigue fracture resistance NCF

Due to an error in fracture sound detection, the number of instruments in the TiN-coated K3 file group was corrected to 11. The median NCF values and ranges of the untreated instruments and the TiN-coated instruments are shown in Table 1. Mann-Whitney analysis revealed that TiN treatment on K3 files significantly decreased the NCF value (p<0.05). The NCF of the Helix file was increased after surface treatment, but the effect was not statistically significant (p>0.05).

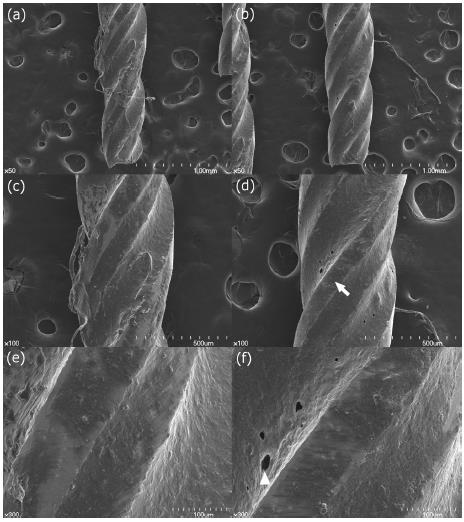

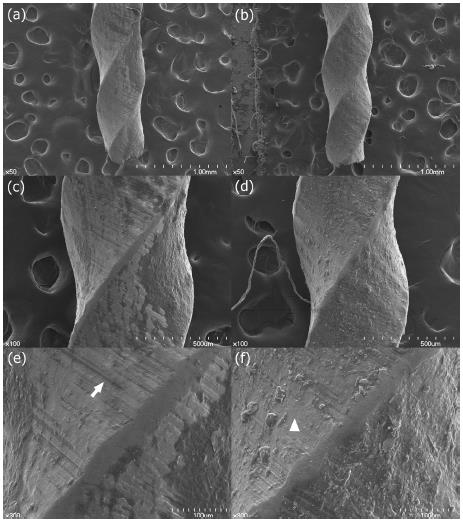

Surface examination under a scanning electron microscope

The lateral surface of the fractured K3 file showed that a TiN coating was formed in the experimental group, but there was no other structural change (Figure 3). The cutting edge of the original instrument was irregular, whereas that of the coated instrument was flat and dull. The Helix NiTi rotary files showed similar results (Figure 4). The untreated instruments showed linear and parallel machining marks, whereas the machining marks were less obvious in the coated instrument, as the marks were covered by the TiN coating.

The representative longitudinal view of original K3 NiTi file under a scanning electron microscope at 50x (A), 100x (C), 300x (E) and TiN-coated K3 NiTi file at 50x (B), 100x (D), 300x (F). Arrow shows the coated surface with a flat and dull cutting edge. Triangle shows uncoated hollow surface.

The representative longitudinal view of original Helix NiTi file under a scanning electron microscope at 50x (A), 100x (C), 300x (E) and TiN-coated Helix NiTi file at 50x (B), 100x (D), 300x (F). Arrow shows the uncoated original surface with linear parallel machining marks. Triangle shows the coated surface with the machining marks partially covered.

DISCUSSION

The purpose of this study was to examine the effect of TiN coating treatment on the cyclic fatigue resistance of two nickel-titanium rotary instruments. The cyclic fatigue resistance of the two TiN-coated NiTi files were not significantly higher than the control group. The instrument surface was coated in TiN in an effort to create a smoother surface and decrease the cyclic fatigue resistance (Peng et al., 2003), but in the present study, TiN coating did not have a similar effect on endodontic NiTi instruments.

When NiTi files are rotated within a curved canal, tensile and compressive forces are continuously placed on the file at the canal curvature (Gambarini, 2001). Cyclic fatigue accumulates, and, with repeated use, NiTi instruments sometimes fracture within the canal. This creates an embarrassing situation for the dentist. Surface defects created during the manufacturing process increase the stress on the instrument during instrumentation (Tripi et al., 2006; Madarati et al., 2008). In fact, smoother instrument surfaces with fewer defects increase the fracture resistance of the instrument.

Titanium nitride (TiN) is an exceptionally strong material, which is coated on metal surfaces to improve surface characteristics such as abrasion and corrosion resistance (Matthews, 1985). However, physical vapor deposition of TiN didn’t significantly increase the fatigue resistance in the present study. The results of the scanning electron microscope imaging showed that in both files TiN coating was formed on the file surface. However, there wasn’t any identifiable structural characteristic that may represent fracture patterns.

The longevity of the aforementioned cutting instruments was improved by increasing the abrasion and corrosion resistance. On the other hand, the instruments were placed under repeated compressive and tensile stresses and fractured due to cyclic fatigue. It is possible that the longevity of the instruments was not improved because of the difference in the type of stress and the fracture method.

During physical vapor deposition, the treatment process affects the thickness and the composition of the TiN film formed (Quinto et al., 1987). If the coating is too thick, the instrument flexibility decreases, and consequently the fatigue resistance decreases. This could be another factor explaining why the fatigue resistance was not improved by the TiN coating. K3 files are known to have a large core diameter and are more rigid than Helix. Helix files have a small core diameter and superior flexibility.

Since K3 and Helix files have different manufacturers, manufacturing processes, and instrument designs, the effect of the TiN deposition process probably had different influence on their initial mechanical characteristics. If the TiN coating process is modified according to the different instrument characteristics and manufacturing processes, TiN may offer more structural benefits. Further studies are needed to investigate this idea. More comprehensive studies on the TiN coating thickness, the changes in smoothness and flexibility after TiN coating, and their subsequent influence on the abrasion and fracture resistances is also needed in the future.

CONCLUSION

Under the limitation of this in vitro study, the TiN coating did not improve the cyclic fatigue resistance of NiTi instruments. Further studies with modified TiN coating process are needed to further investigate possible benefits of TiN coating on NiTi instruments.

Notes

References

-

SB Alapati, WA Brantley, TA Svec, JM Powers, JC Mitchell, Scanning electron microscope observations of new and used nickel-titanium rotary files, J Endod, (2003), 29(10), p667-669.

[https://doi.org/10.1097/00004770-200310000-00014]

-

ME Anderson, JW Price, P Parashos, Fracture resistance of electropolished rotary nickel-titanium endodontic instruments, J Endod, (2007), 33(10), p1212-1216.

[https://doi.org/10.1016/j.joen.2007.07.007]

-

R Boxman, S Goldsmith, Principles and applications of vacuum arc coatings, IEEE Trans Plasma Sci, (1989), 17(5), p705-712.

[https://doi.org/10.1109/27.41186]

-

G Gambarini, Cyclic fatigue of ProFile rotary instruments after prolonged clinical use, Int Endod J, (2001), 34(5), p386-389.

[https://doi.org/10.1046/j.1365-2591.2001.00259.x]

-

Y Haikel, R Serfaty, G Bateman, B Senger, C Allemann, Dynamic and cyclic fatigue of engine-driven rotary nickel-titanium endodontic instruments, J Endod, (1999), 25(6), p434-440.

[https://doi.org/10.1016/S0099-2399(99)80274-X]

-

UM Li, BS Lee, CT Shih, WH Lan, CP Lin, Cyclic fatigue of endodontic nickel titanium rotary instruments: static and dynamic tests, J Endod, (2002), 28(6), p448-451.

[https://doi.org/10.1097/00004770-200206000-00007]

-

AA Madarati, DC Watts, AJ Qualtrough, Factors contributing to the separation of endodontic files, Br Dent J, (2008), 204(5), p241-245.

[https://doi.org/10.1038/bdj.2008.152]

-

A Matthews, Titanium nitride PVD coating technology, Surf Eng, (1985), 1(2), p93-104.

[https://doi.org/10.1179/sur.1985.1.2.93]

-

S PalDey, SC Deevi, Single layer and multilayer wear resistant coatings of (Ti,Al)N: a review, Mat Sci Eng A-Struct, (2003), 342(1-2), p58-79.

[https://doi.org/10.1016/S0921-5093(02)00259-9]

-

P Parashos, I Gordon, HH Messer, Factors influencing defects of rotary nickel-titanium endodontic instruments after clinical use, J Endod, (2004), 30(10), p722-725.

[https://doi.org/10.1097/01.DON.0000129963.42882.C9]

-

P Parashos, HH Messer, Rotary NiTi instrument fracture and its consequences, J Endod, (2006), 32(11), p1031-1043.

[https://doi.org/10.1016/j.joen.2006.06.008]

-

Z Peng, H Miao, L Qi, S Yang, C Liu, Hard and wear-resistant titanium nitride coatings for cemented carbide cutting tools by pulsed high energy density plasma, Acta Mater, (2003), 51(11), p3085-3094.

[https://doi.org/10.1016/S1359-6454(03)00119-8]

-

DT Quinto, GJ Wolfe, JP C, High Temperature microhardness of hard coatings produced by physical and chemical vapor deposition, Thin Solid Films , (1987), 153(1-3), p19-36.

[https://doi.org/10.1016/0040-6090(87)90166-0]

-

B Sattapan, GJ Nervo, JE Palamara, HH Messer, Defects in rotary nickel-titanium files after clinical use, J Endod, (2000), 26(3), p161-165.

[https://doi.org/10.1097/00004770-200003000-00008]

-

E Schafe, Effect of physical vapor deposition on cutting efficiency of nickel-titanium files, J Endod, (2002), 28(12), p800-802.

[https://doi.org/10.1097/00004770-200212000-00002]

-

TR Tripi, A Bonaccorso, GG Condorelli, Fabrication of hard coatings on NiTi instruments, J Endod, (2003), 29(2), p132-134.

[https://doi.org/10.1097/00004770-200302000-00011]

-

TR Tripi, A Bonaccorso, GG Condorelli, Cyclic fatigue of different nickel-titanium endodontic rotary instruments, Oral Surg Oral Med Oral Pathol Oral Radiol Endod, (2006), 102(4), pe106-114.

[https://doi.org/10.1016/j.tripleo.2005.12.012]

-

JH Yao, SA Schwartz, TJ Beeson, Cyclic fatigue of three types of rotary nickel-titanium files in a dynamic model, J Endod, (2006), 32(1), p55-57.

[https://doi.org/10.1016/j.joen.2005.10.013]

-

G Zelada, P Varela, B Martin, JG Bahillo, F Magan, S Ahn, The effect of rotational speed and the curvature of root canals on the breakage of rotary endodontic instruments, J Endod, (2002), 28(7), p540-542.

[https://doi.org/10.1097/00004770-200207000-00014]