Influence of light-curing on the translucence change and color stability of amine-free dual-cured resin cements

; Bo-Ram Lee

; Bo-Ram Lee ; Bin-Na Lee

; Bin-Na Lee ; Hoon-Sang Chang

; Hoon-Sang Chang ; Yun-Chan Hwang

; Yun-Chan Hwang ; Won-Mann Oh

; Won-Mann Oh ; In-Nam Hwang*

; In-Nam Hwang*

Abstract

The aim of this study was to investigate the influence of light-curing on the translucency change and color-stability of amine(tertiary)-free dual-cured resin cements after accelerated aging. Two curing modes (dual-curing and self-curing) were applied on three dual-cured resin cements (Duo-Link Universal [DLU], Nexus Third Generation [NX3] and RelyX Ultimate [RXU]) in this study. Ten specimens were fabricated for each group. In dual-cured groups only, light-activation was performed with polywave-LED curing unit (Bluphase, Ivoclar Vivadent, Schaan, Liechtenstein), where each sides of the samples were photo-polymerized for 60 seconds. Self-cured groups were kept in the dark storage for 24 hours. The color of the specimens was measured with spectrocolorimeter (NF999, Nippon Denshoku, Japan) after 24 hours of making samples. After the initial color measurements, the specimens were subjected to accelerated aging procedure. Spectrophotometric analysis was carried out on day 7, day 14, day 21 and day 28 of accelerated aging in 60 ℃ of distilled water. The color characteristics, color difference (ΔE*), and translucency parameter (TP) of specimens were calculated according to the CIE L*a*b* color system before and after aging. All the ΔE* values and TP values were analyzed by 2-way analysis of variance.

After aging, all groups revealed clinically perceptible color differences (ΔE*>3.3). Differences in ΔE* values of self-cured groups were significantly higher than those of dual-cured groups in NX3 and RXU. But there were no significant differences in ΔE* between dual-cured mode and self-cured mode of DLU. All mean b* values increased after aging. All mean L* values decreased after aging except for self-cured RXU cement. TP values also decreased with aging. TP values of self-cured groups were significantly lower than those of dual-cured groups in NX3 and RXU. Hence, in conclusion, despite the absence of tertiary amine in the dual-cured resin cements, such resin cements should be polymerized with the dual-cure modes to ensure long-term color-stability.

초록

본 연구는 3차아민을 포함하지 않은 이원중합 레진시멘트의 광중합 여부가 색안정성 및 투명도 변화에 미치는 영향을 알아보고자 시행되었다. 3종의 이원중합 레진시멘트 Duo-Link Universal (DLU), Nexus Third generation (NX3), RelyX Ultimate (RXU)를 두군으로 분류하여 군 당 10개의 시편을 제작해서, 이원중합군에서는 3종의 이원중합 레진시멘트를 LED광조사기(Bluphase, Ivoclar Vivadent, Schaan, Liechtenstein)로 양면을 각각 60초씩 광중합하였고, 자가중합군에서는 광조사하지 않고 빛이 차단된 곳에 24시간 보관하였다. 제작된 시편을 24시간 후 분광색채계측기(NF999, Nippon Denshoku, Japan)로 색의 특성을 측정하였다. 광선이 차단된 60℃ 증류수에서 7일, 14일, 21일, 28일간 가속시험 후 같은 조건에서 CIE L*a*b* 값을 측정하여 색차와 투명도 변화량을 산출하고 비교 분석한 바 다음의 결과를 얻었다. 28일 동안 가속시험 후 모든 군에서 임상적으로 인지 가능한 색변화를 보였다(ΔE*>3.3). NX3, RXU군에서는 색변화량이 이원중합군에 비해 자가중합군에서 유의하게 높게 나타났으나, DLU군에서는 자가중합군과 이원중합군간 색변화량의 유의한 차이가 없었다. 레진시멘트의 종류에 관계없이 가속시험 시 시간경과에 따라 b* 값은 증가하는 양상을, RXU 자가중합군을 제외하고 L*값은 감소하는 양상을 보였다. 28일의 가속시험 후 투명도 값은 모든 군에서 감소하였고, NX3, RXU는 자가중합군에서의 투명도 값이 이원중합군에서 보다 유의하게 낮게 나타났다(p<0.05). 따라서 본 연구의 결과에 따르면 광중합의 유무는 장기간의 색 안정성 및 투명도에 유의한 영향을 줄 수 있을 것으로 사료된다.

Keywords:

Color stability, Dual-cured resin cements, Light-curing, Translucence change키워드:

색안정성, 이원중합레진시멘트, 투명도 변화Introduction

The resin-luting agents have been widely used because of their high strength, low solubility and esthetic appearance. An increasing number of products are available today.

The majority of resin-luting materials employ dual-cured polymerization, which combines the desirable properties of both chemically-cured and light-cured cements (1-3). There are a lot of superior properties such as a wide range of shades, rapid initial hardening and further curing by the chemical catalyst, and extended working time (1, 2). On a two-paste system, the dual-cured resin cements have both initiation systems. The base paste usually contains camphoroquinone (CQ), aliphatic amine, and aromatic tertiary amine. And the catalyst paste contains benzoyl peroxide (1).

Change in the color of resin based materials is multifactorial, including extrinsic staining and intrinsic discoloration. Intrinsic factors involve physico-chemical discoloration reactions in the composite matrix, in surface and in deeper layers of the material, triggered by thermal energy, UV irradiation, or humidity (4). Chemical discoloration has been attributed to oxidation in the amine accelerator and inhibitors, oxidation of the unreacted methacrylate groups, and oxidation in the structure of the polymer matrix (4, 5). The appearance of resin based materials changes over time in relation to the water accumulation.

Resin cements may go through internal discoloration, which may show-through and affect the appearance of translucent all-ceramic restorations. Thus, color stability of resin cements is required by dental clinicians in cases of aesthetic restoration such as porcelain or indirect composite (6).

The manufacturers of dual-cured resin cements try to develop these materials which can be effectively polymerized solely by chemical reaction. The chemical curing is recommended for cementation of the restorations where light penetration is compromised. However, the majority of dual-cured resin cement does not reach comparable hardness values or conversion degree when tested in the presence or absence of light-curing. Among the commercial dual-cured resin cements, some have guaranteed for color stability on long term. The manufacturers claim that Nexus Third Generation (Kerr, Orange, CA, USA) and Rely X Ultimate (3M ESPE, St Paul, MN, USA) cements have a proprietary chemistry that eliminates concerns about color changes, though most dual-cured cements containing amines often change in color.

Aging simulates the effects of long-term exposure to environmental conditions through an artificial weathering process that involves temperature, humidity, and light exposure (7). Therefore, the present study investigated the influence of light-curing on the color stability and translucency of dual-cured resin cements after accelerated aging.

Materials and Methods

1. Preparation of the specimens

Two curing modes (dual-cured, self-cured) of three dual-cured resin cements (Duo-Link Universal [DLU], Nexus third generation [NX3] and Rely X Ultimate [RXU]) were selected for this study. Information about the materials is listed in Table 1.

For making standardized disc-shaped specimens of color stability, plates (4 mm thick) with holes of 6 mm diameter were used as molds. And for making specimens of translucency, plates (1 mm thick) with holes of 6 mm diameter were used as molds. Metal plates and translucent acrylic plates were used for self-cured mode and dual-cured mode, respectively. After manipulation according to the manufacturer’s instructions, the cements were inserted into the molds and covered with clear celluloid strips (Mylar film) and glass slides on the top and bottom of the hole. And then, the plates were pressed by c-clamps. Ten specimens were fabricated for each group.

In dual-cured groups, the tip of a polywave LED device (Bluephase Style, Ivolcar Vivadent, Amherst, NY, USA) was positioned in contact with the surface. And irradiation was performed on both sides for 60 seconds with a light intensity of 1100 mW/cm2(6, 8). After light curing, the specimens were separated and stored in the dark at room temperature for 24 hours.

In self-cured groups, the specimens were kept for 30 minutes without light curing (6, 8), and then separated from molds. They were immediately stored in a dark environment at room temperature for 24 hours.

Finally, the specimens were manually polished with humid abrasive papers (1200, 1500, 2000 grit) (8). Standardization of thickness was verified with a digital electronic caliper. Polished specimens were numbered by indentation.

2. Color and color difference (ΔE*) measurements

Each CIE L*a*b* value was measured with a spectrocolorimeter (NF999, Nippon, Denshoku, Tokyo, Japan) at the time of baseline (24 hours after curing), 1 week, 2 weeks, 3 weeks and 4 weeks later.

Calibration of the equipment was performed immediately before the series of measurements using a white tile supplied by the manufacturer. The values were based on D65 CIE illuminant and a 10° observer over a white background (L*= 92.97, a*= - 0.09, b* = 0.01) (8). CIE L*a*b* system is composed of 3 axes: L* (lightness, from 0 = black up to 100 = white), a* (from -a = green up to +a = red) and b* (from -b = blue up to +b = yellow) (9, 10). Each average value was decided by measuring the specimen 3 times.

After the first color measurements of the specimens with the CIE L*a*b* system, the specimens were subjected to accelerated aging procedure using a water bath circulator (MRC-1011D, Monotech Co., Daegu, Korea) at 60℃ for 28 days (8). After immersion, spectrocolorimetric analysis was made every week of accelerated aging time under the same conditions using the same procedures.

Color change was obtained through this equation (11-13) :

ΔE* = [(ΔL*)2 + (Δa*)2 + (Δb*)2]½

The adopted classification of ΔE values was determined by the National Bureau of Standards (NBS) that considers: 0.0 to 0.5 values: extremely slight change; 0.5 to 1.5: slight change; 1.5 to 3.0: perceivable change; 3.0 to 6.0: marked change; 6.0 to 12.0: extremely marked change; 12.0 or more: change to another color (13). To define the relationship between the degree of visual color differences and the ranges of colorimetric differences, colorimetric differences above 3.3 were considered as ‘perceptible differences’ (14).

3. Translucency parameter measurements

The translucency parameter (TP) refers to the color difference for a uniform thickness of a substance against a black or white background (14, 15), and corresponds to common visual assessments of translucency (14).

After 24 hours, the CIE L*a*b* value of the materials was measured separately by using a spectrocolorimeter, against two backings: a black background (L* = 19.73, a* = -2.07, b* = 1.36) and a white background (L* = 92.97, a* = -0.09, b* = 0.01).

The translucency of the materials at 1 mm thickness was calculated by using the TP formula. TP = [(L*w -L*B)2+(a*w -a*B)2+(b*w -b*B)2]1/2, where the subscript ‘W’ refers to CIE L*a*b* values for each 1 mm-thick specimen on the white background, and the subscript ‘B’ refers to the values for specimens on the black background (11, 12, 15). Each average value was decided by measuring the specimen 3 times.

After the first color measurements of the specimens with the CIE L*a*b* system, the specimens were subjected to accelerated aging procedure using a water bath circulator (MRC-1011D, Monotech Co., Daegu, Korea) at 60℃ for 28 days (8). After immersion, spectrocolorimetric analysis was made every week of accelerated aging time under the same conditions using the same procedures.

4. Statistical analysis

The statistical analysis was performed by using SPSS 21.0 for windows (SPSS, Chicago, IL, USA). The obtained data were submitted to the 2-way analysis of variance (2-way ANOVA; factors were curing mode and cement type) with a Least Significant Difference (LSD) test for multiple comparison. All statistical testing was performed at a preset alpha of 0.05.

Results

1. Color and color difference (ΔE*) measurements

Table 2 shows the color differences after 4 weeks of accelerated aging. After 28 days on accelerated aging, all groups revealed clinically perceptible color differences (ΔE*>3.3). Regardless of type of the resin cements, all mean L* values decreased excepting self-cured RXU cement. Negative values of ΔL* after aging indicate darker material appearance. All mean b* values increased after aging. Positive values of Δb* after aging indicate yellowish material appearance. All Δa* values were quite constant during the experiment.

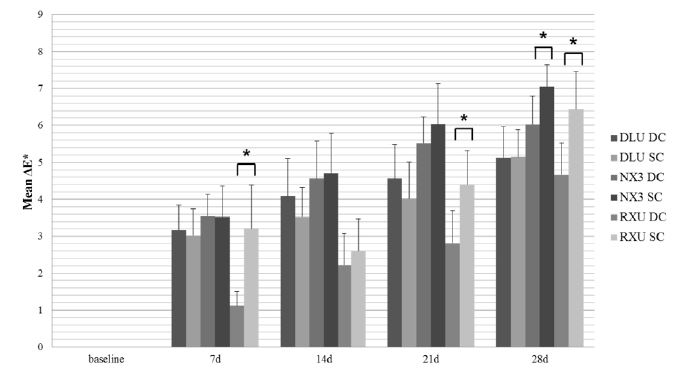

Statistically significant differences in ΔE* were found between dual-cured mode and self-cured mode of both NX3 and RXU, respectively. Differences in ΔE* values of self-cured group were significantly higher than those of dual-cured groups (p<0.05; Figure 1). In contrast, there were no significant differences in ΔE* between dual-cured mode and self-cured mode of DLU cement.

2. Translucency parameter change measurements

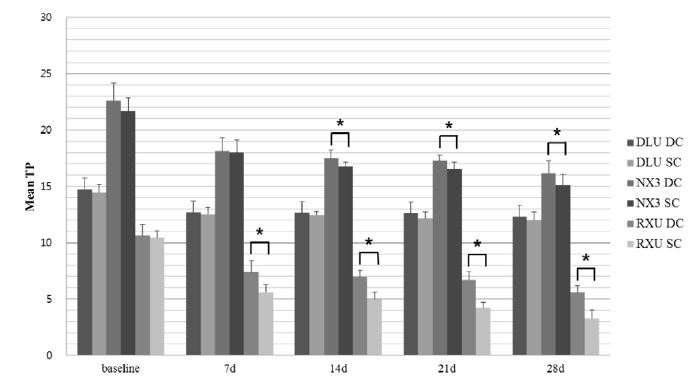

After 28 days on accelerated aging, TP values were decreased. Negative values of ΔTP after aging indicate more opaque material appearance. The TP values exhibited the following trend: RXU < DLU < NX3 (Figure 2). The TP values of dual-cured groups were significantly higher than those of self-cured groups in NX3 and RXU (p<0.05; Figure 2).

Discussion

Color-stability is important for contemporary resin-based materials (16). Clinical experience demonstrates that resin cements change their optical properties over time and internal discolorations often require restoration replacement (17).

Previous investigations reported that the color changes of resin composites were caused by the following factors: the chemical activator, resin initiator and inhibitor, activator progress, polymer quality, monomer, type and quantity of filler, oxidation of unreacted carbon-carbon double bonds, ultraviolet light illumination, heat, and water (18). The phenomena of sorption and solubility may serve as precursors to physical and chemical processes that cause deleterious effects on the structure of the resin matrix. These effects include swelling, plasticization, oxidation and hydrolysis. Hence, there is a decrease of the color stability, promoting higher susceptibility to staining. Oxidation of residual unreacted carbon-carbon double bonds and degradation of residual amines and result in the formation of yellowing compounds. All amines are known to form by-products during photoreaction, which tend to cause yellow to red/brown discolorations under the influence of temperature, humidity, or ultraviolet light (16, 19). Especially, aromatic tertiary amines used in self-cured or dual-cured resin cements are more likely to oxidize than aliphatic amines used in light-cured materials. Therefore, light-cured resin cements are generally expected to have higher color stability than dual-cured cements (3, 19).

In addition, the physicochemical properties of monomers used in a resin matrix may influence resistance to staining. Triethylene glycol dimethacrylate (TEGDMA) monomer is responsible for higher rates of water sorption in resin-based materials due to its hydrophilic ether linkage. Water uptake by bisphenylglycidyl dimethacrylate (bis-GMA)-based resins may decrease with the partial substitution of TEGDMA by urethane dimethacrylate (UDMA) (3, 9).

Composite resins containing larger filler particles may be more susceptible to discoloration. However, we could not identify them since the manufacturers did not disclose the ingredients of materials.

Although photosensitizer camphorquinone (CQ) has been widely used since visible-light curable composites were developed, it has some shortcomings. CQ presents an intense yellow coloration and poor photobleaching. It requires a co-initiator such as amine. Because these factors negatively impact the optical properties over time, other photoinitiator systems have been investigated to replace or act jointly with CQ, such as phenylbis (2,4,6-trimethylbenzoyl)phosphine oxide (BAPO) and diphenyl (2,4,6-trimethylbenzoyl)- phosphine oxide (TPO). These photoinitiators do not need an amine co-initiator and might react by direct cleavage. According to previous findings, the use of a photoinitiator system containing TPO might improve the color stability of resin composites while attaining similar physicochemical properties (25). As mentioned previously, the manufacturers claimed that NX3 and RXU cements have a specific chemistry that eliminates concerns about color changes. Therefore, we supposed that they may have the alternative initiator. Absorption peak of newly developed composite which contain an alternative photoinitiator is in the near ultraviolet region and extends slightly into the visible wavelengths (< 420 nm). For this reason, polywave LED curing unit (Blue phase) was used in the present study.

All mean b* values increased after aging in this investigation. It suggests that resin based materials tend to cause yellowing after aging. According to some authors, yellowing of a material over time could be related to an increased amount of camphorquinone in its formulation. Another explanation could be the exposition of Bis-GMA-based material to heat and ultraviolet light (3).

Opacity can give the cement the ability to cover underlying tooth discolorations, while it may render the restoration less natural (3). According to previous studies, both size and quantity of filler particle have a key importance in translucency. Actual color of each product varies despite the use of the same shades for all materials (15). More chromatic shades of commercial resin composites were less translucent (10). Even though NX3 and RXU are the same shade, they had a noticeable difference of TP values in baseline. The translucency of composites decreases as the difference between the refraction indexes of the resin matrix and the amount of filler increase (15). As with other experiments, all groups became more opaque after accelerated aging in the current study (3, 12). Exact reason for the change in translucency and the different behavior of the various cements still needs to be studied. However, it is believed that partial debonding of the filler from the resin as a result of hydrolysis and stress cracks within the polymer matrix, may increase opacity and alter the color appearance (19). Accelerated aging may have caused some degradation of the resin cements, so increased color change and the decreased translucency in this study may have resulted from this disintegration.

The results of this experiment correspond to the generally known facts that self-curing has lower color stability than dual polymerization. That is, there are significant differences between the two curing modes in color stability and translucency. In addition, the ΔE* of products claiming amine free as NX3 and RXU, was in the range of the other cement.

This study had some limitations. The type and amount of alternative photoinitiators included in resin cement were not known precisely because manufacturers considered it to be commercially sensitive. Thus, more studies are necessary that examine color and translucency changes in relation to the product composition.

Conclusion

In conclusion, this study investigated the influence of light curing on the color stability and translucency of amine free dual-cured resin cements after accelerated aging. Even if the dual-cured resin cements did not contain tertiary amine, they should be polymerized with the dual modes to ensure long-term color stability.

Within the limitations of the present study, it was concluded that the presence or absence of light curing significantly affected the color stability and translucency over the long term.

References

-

Komori P, Paula A, Martin A, Tango R, Sinhoreti M, Correr-Sobrinho L. Effect of light energy density on conversion degree and hardness of dual-cured resin cement. Oper Dent. 2010;35(1):120-4.

[https://doi.org/10.2341/09-126-L]

-

Meng X, Yoshida K, Atsuta M. Hardness development of dual-cured resin cements through different thicknesses of ceramics. Dent Mater J. 2006;25(1):132-7.

[https://doi.org/10.4012/dmj.25.132]

-

Archegas LRP, Freire A, Vieira S, de Menezes Caldas DB, Souza EM. Colour stability and opacity of resin cements and flowable composites for ceramic veneer luting after accelerated ageing. J Dent. 2011;39(11):804-10.

[https://doi.org/10.1016/j.jdent.2011.08.013]

- Borges AL, Costa AK, Saavedra GS, Komori PC, Borges AB, Rode SM. Color stability of composites: effect of immersion media. Acta Odontol Latinoam. 2011;24(2):193-9.

-

Kilinc E, Antonson SA, Hardigan PC, Kesercioglu A. Resin cement color stability and its influence on the final shade of all-ceramics. J Dent. 2011;39:e30-e6.

[https://doi.org/10.1016/j.jdent.2011.01.005]

-

Koishi Y, Tanoue N, Atsuta M, Matsumura H. Influence of visible‐light exposure on colour stability of current dual‐curable luting composites. J Oral Rehabil. 2002;29(4):387-93.

[https://doi.org/10.1046/j.1365-2842.2002.00823.x]

-

Dikicier S, Ayyildiz S, Ozen J, Sipahi C. Effect of varying core thicknesses and artificial aging on the color difference of different all-ceramic materials. Acta Odontol Scand. 2014;72(8):623-9.

[https://doi.org/10.3109/00016357.2013.879997]

-

Song HJ, Park SJ, Hwang YC, Oh WM, Hwang IN. Color stability of the resin cements with accelerated aging. Restor Dent Endod. 2008;33(4):389-96.

[https://doi.org/10.5395/JKACD.2008.33.4.389]

-

Magalhães APR, Cardoso PdC, de Souza JB, Fonseca RB, Pires‐de‐Souza FdCP, Lopez LG. Influence of activation mode of resin cement on the shade of porcelain veneers. J Prosthodont. 2014;23(4):291-5.

[https://doi.org/10.1111/jopr.12098]

-

Yu B, Lee YK. Influence of color parameters of resin composites on their translucency. Dent Mater. 2008;24(9):1236-42.

[https://doi.org/10.1016/j.dental.2008.01.016]

-

Korkmaz Ceyhan Y, Ontiveros JC, Powers JM, Paravina RD. Accelerated aging effects on color and translucency of flowable composites. J Esthet Restor Dent. 2014;26(4):272-8.

[https://doi.org/10.1111/jerd.12093]

-

Paravina RD, Ontiveros JC, Powers JM. Accelerated aging effects on color and translucency of bleaching-shade composites. J Esthet Restor Dent. 2004;16(2):117-26.

[https://doi.org/10.1111/j.1708-8240.2004.tb00018.x]

-

Domingos PAdS, Garcia PPNS, Oliveira ALBMd, Palma-Dibb RG. Composite resin color stability: influence of light sources and immersion media. J Appl Oral Sci. 2011;19(3):204-11.

[https://doi.org/10.1590/S1678-77572011000300005]

-

Ikeda T, Sidhu SK, Omata Y, Fujita M, Sano H. Colour and translucency of opaque‐shades and body‐shades of resin composites. Eur J Oral Sci. 2005;113(2):170-3.

[https://doi.org/10.1111/j.1600-0722.2005.00205.x]

-

Kim D, Park S. Evaluation of resin composite translucency by two different methods. Oper Dent. 2013;38(3):e76-e90.

[https://doi.org/10.2341/12-085-L]

-

Janda R, Roulet JF, Latta M, Steffin G, Rüttermann S. Color stability of resin‐based filling materials after aging when cured with plasma or halogen light. Eur J Oral Sci. 2005;113(3):251-7.

[https://doi.org/10.1111/j.1600-0722.2005.00217.x]

-

Buchalla W, Attin T, Hilgers RD, Hellwig E. The effect of water storage and light exposure on the color and translucency of a hybrid and a microfilled composite. J Prosthet Dent. 2002;87(3):264-70.

[https://doi.org/10.1067/mpr.2002.121743]

-

Hosoya Y. Five-year color changes of light-cured resin composites: influence of light-curing times. Dent Mater. 1999;15(4):268-74.

[https://doi.org/10.1016/S0109-5641(99)00046-9]

-

Ghavam M, Amani-Tehran M, Saffarpour M. Effect of accelerated aging on the color and opacity of resin cements. Oper Dent. 2010;35(6):605-9.

[https://doi.org/10.2341/09-161-L]