Effects of Pre-Sintering Surface Treatment and Liner Application on the Shear Bond Strength of Zirconia and Veneer Ceramic

This study was intended to investigate the effect of applying liner for chemical bonding and physical surface roughness created on Yttria-toughened zirconia (YTZ core) by using a polishing tool before sintering on the bond strength between the two materials. YTZ blocks(Fine Base, K&F, Korea, 15mm×15mm ×4mm) were cut using a low-speed cutter. Plate-shaped specimen (6mm×6mm×3mm) was fabricated by sintering after giving surface roughness according to three kinds of polishing tools. Depending on whether or not to use liner, 60 specimens were divided into two groups ZP(non-liner), ZLP(liner), and the two groups were subdivided into three groups respectively in accordance with polishing tools used, totaling six groups (n=10). The surface roughness (Ra) values and shapes before sintering were observed, and shear bond strength after veneer ceramic plasticity was measured with a universal testing machine. For a test of the significance, a one-way ANOVA was performed, and Tukey's multiple comparison test was conducted. The observation of fracture surfaces using an optical microscope revealed that the surface roughness was SZ(1.10±0.76㎛)<CZ(1.92±0.41㎛)<PZ(3.08±0.58㎛). In the case of ZP Group, the shear bond strength was SZ(27.82±1.97㎫)<PZ(30.94±3.84㎫)<CZ(38.56±2.09㎫) in order, and CZ showed the highest shear bond strength of all experimental groups(p<0.05). As for ZLP Group, there was no statistically significant difference in the shear bond strength between groups with SLZ(26.7±2.8㎫), PLZ(27.1±1.6㎫), CLZ(28.1±3.2㎫)(p>0.05). The research results showed that the bond strength of YTZ core and veneering ceramic was further improved by physical surface treatment before sintering, rather than by chemical bonding through liner surface treatment.

Keywords:

Zirconia, Ceramic, Surface treatment, Shear bond strength, Liner additionINTRODUCTION

In the clinical field, all-ceramic crown restoration is a widely used for replacement of porcelain-fused metal crown restoration because of the former’s excellent aesthetics and biocompatibility. Yttria-toughened zirconia (YTZ), which has outstanding physical and mechanical properties, is particularly favored as an all-ceramic crown core (Manicone et al., 2007).

In the past, YTZ core was difficult to use commercially in dental applications because its contraction and high intensity after sintering resulted in processing problems. The introduction of computer-aided design/ manufacturing increased the precision of YTZ core restoration, and preliminarily sintered YTZ core enabled the production of high-intensity aesthetic prosthesis by the ready processing of sintered bodies (Luthardt et al., 2001; Luthardt et al., 2002).

All-ceramic crown restoration is generally applied to veneer ceramic is laid onto the upper segment of the crown after a YTZ core is fabricated. The results are aesthetically excellent but the veneer ceramic exhibits poor absorption of elastic energy, thereby presenting a high possibility of fracture resulting from low tensile force and fine structural defects (Albakry et al., 2003; Aboushelib et al., 2008).

Numerous reports regarding failure in the interface between YTZ core and veneer ceramic have been published; in particular, many are about cases in which only veneer ceramic was unaffected by YTZ core fracture (Sundh et al., 2004). Fracture resulting from the low strength of bonding between YTZ core and veneer ceramic is caused by stress distribution that stems from differences in thermal expansion coefficient, low wettability of YTZ core with veneer ceramic, contraction resulting from plasticity, heat- or stress load-induced YTZ core crystal transformation in the interface between YTZ core and veneer ceramic, and defects in manufacturing (De Jager et al., 2005). Research on improving the strength of bonding between YTZ core and veneer ceramic has been conducted, with a view to resolving mechanical or chemical defects.

Aboushelib et al(2005) reported that among surface treatment methods, sandblasting did not affect bond strength when veneer ceramic is used and that bond strength increased when a liner was applied. Wegner and Kern(2000) observed excellent bond strength under sandblasting with 110-μm aluminum oxide. Derand et al(2005) reported that the prominent structure of an irregular surface increased surface energy and wettability, thereby improving the strength of bonding between YTZ core and veneer ceramic.

Many experiments on the strength of bonding between YTZ core and veneer ceramic have been performed. Considerable research has been devoted to this subject matter, but none focuses on the effects of pre-sintering surface treatment of YTZ core on bond strength. The present study analyzed the effects of physical surface roughness created on YTZ core by using a grinding tool prior to sintering. This process was implemented to reduce failure in YTZ core–veneer ceramic restoration. The study also investigated the effects of liner treatment (for chemical bonding) on the strength of bonding between YTZ and veneer ceramic. The results can serve as reference for successful prosthesis production

MATERIALS AND METHODS

1. Preparation of YTZ specimens

Table 1 lists the specifications of the YTZ core, liner, and veneer ceramic used in this study. A total of 60 specimens were fabricated by the cutting of a YTZ block (Fine Base, K&F, Korea) into rectangular 15 mm × 15 mm × 4 mm specimens that were parallel piped using a low-speed saw (Model-650, South Bay Technology, USA). The specimens were classified into six groups, with 10 specimens each.

Table 2 displays the codes of the specimens and their surface pre-treatment conditions. The specimens were divided into two groups, the liner- and non-liner treated groups (ZP and ZLP groups, with 30 specimens each). These two groups were again subdivided into three groups for the experiments on different levels of surface roughness. Grinding on YTZ core prior to the sintering of the plate-type specimens was conducted with a carborundum stone point (GC#44, Sunil, Korea), a paper cone point (Monose Mfg., Japan), and a silicone rubber point (Eve Ecoceram NK, EVE Ernst Vetter GmbH, Germany). Grinding from the right side to the left side of the specimens was conducted 10 times, after which the specimens were placed in a calcination furnace (Zirkonofen 600, Zirkonzahn GmbH, Italy). The furnace temperature was increased from 650 to 1,500 °C at a heating rate of 8 °C/min. The specimens were sintered for 2 hours (Table 3). The final specimen specifications after sintering were 6 mm ×6 mm × 3 mm.

2. Liner application, Ceramic veneering, and firing.

Table 4 illustrates the sintering schedule for ceramic veneer and liner application. Each specimen was ultrasonically cleaned for 10 min after surface pre-treatment. The liner (Zirliner, Ivoclar Vivadent, Liechtenstein) was not sprayed onto the ZP group, but 1.0 to 0.2 mm of liner was sprayed onto the ZLP group after cleaning. Liner thickness was measured using a micrometer (MDC-SB, Mitsutoyo, Tokyo, Japan).

Cylindrical silicon mode was used to strengthen the liner and veneer ceramic, with each specimen having the same contact area and size. Veneer ceramic (Zirmax, Alphadent, Korea) of uniform moisture was mixed on a wetting palette in a mold with an internal diameter of 4 mm and a height of 3 mm. The plasticity of the liner and veneer ceramic was induced in the same calcination furnace (Dagussa Dental Co., Germany) according to the plasticity temperature specified by the manufacturer.

3. Evaluation of surface morphology and surface roughness

In order to comparatively observe surface roughness created by grinding prior to sintering, a surface measurement system (SJ-400, Mitutoyo Co., Kanagawa, Japan) was used to measurea 4.0-mm distance from the central area adjusted by 0.5-mm/s movement in each specimen five times. The average roughness (Ra) of each specimen was recorded. Surface shape was observed using a 3-dimensional digital microscope (VHX-600, Keyence Co., Japan).

4. Shear bond test and failure mode analysis

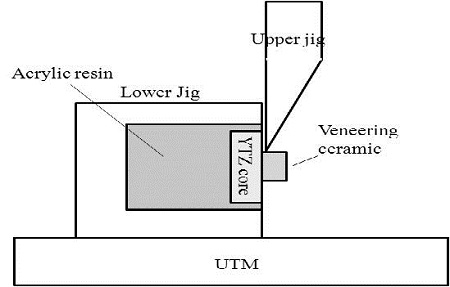

After veneer ceramic sintering, the 60 specimens were embedded with acrylic resin to create cylindrical specimens with a diameter of 30 mm and a height of 20 mm. This process enabled the fixing of the specimens onto a jig for the measurement of shear bond strength. Fixing was performed so that load was delivered in parallel with the bonded surface between YTZ core and veneer ceramic. The maximal load was subsequently measured using a universal testing machine (Model 8871, Instron, USA) with cross head speed at 0.5 mm/min (Figure 1).

For the analysis of fracture surfaces, fracture patterns in the bonded interfaces were observed using an optical microscope (SZX7, Olympus, Japan).

5. Statistical analysis

To determine significance, one-way ANOVA was conducted with SPSS 20.0 for Windows (SPSS Inc., Illinois, USA), after which Tukey’s multiple comparison test was performed.

RESULTS

1. Observations of surface roughness prior to sintering

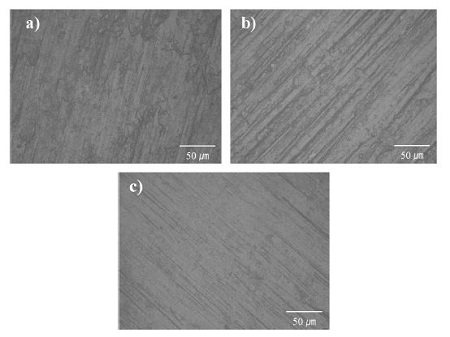

An experiment for observing the physical surface roughness characteristics of YTZ core prior to sintering was conducted using a surface measurement system (SJ-400, Mitutoyo Co., Kanagawa, Japan) and a 3-dimensional digital microscope. On the surfaces of CZ specimens polished with the carborundum stone point, small particles together with trace lines were observed. PZ specimens polished with the paper cone point exhibited very rough trace lines and small particles, but the CZ specimens did not present rough trace lines. Only fine trace lines were observed in the SZ group polished with the silicon rubber point (Figure. 2).

The average surface roughness values of the PZ, CZ, and SZ specimens were 3.08 ± 0.58, 1.92 ± 0.41, and 1.10 ± 0.76 μm, respectively (Table 5). in the same column are significantly different (p<0.05, Tukey’s method).

2. Shear bond strength and fracture pattern

Table 6 show the analysis results for the shear bond strengths and fracture patterns of YTZ core and veneer ceramic. The CZ group polished only with the carborundum stone point had the highest shear bond strength at 38.56±2.09 MPa. The shear bond strengths of the PZ group polished with the paper cone point and the SZ group polished with the silicon rubber point were 30.94±3.8 and 27.82±1.97 MPa, respectively. Those of the CLZ group polished with the carborundum stone point and then sprayed with liner, the PLZ group polished with the paper cone point and sprayed with liner, and the SLZ polished with the silicon rubber point and sprayed with liner were 22.73 ±2.9, 21.90±2.40, and 22.10±1.69 MPa, respectively.

Shear bond strength was high in the order of the CZ, PZ, and SZ groups in the ZP group with the CZ group having the highest shear bond strength (p<0.05). Statistically significant differences were found among all the experimental groups (p<0.05), but none were observed among the SLZ, PLZ, and CLZ specimens under the ZLP group (p>0.05).

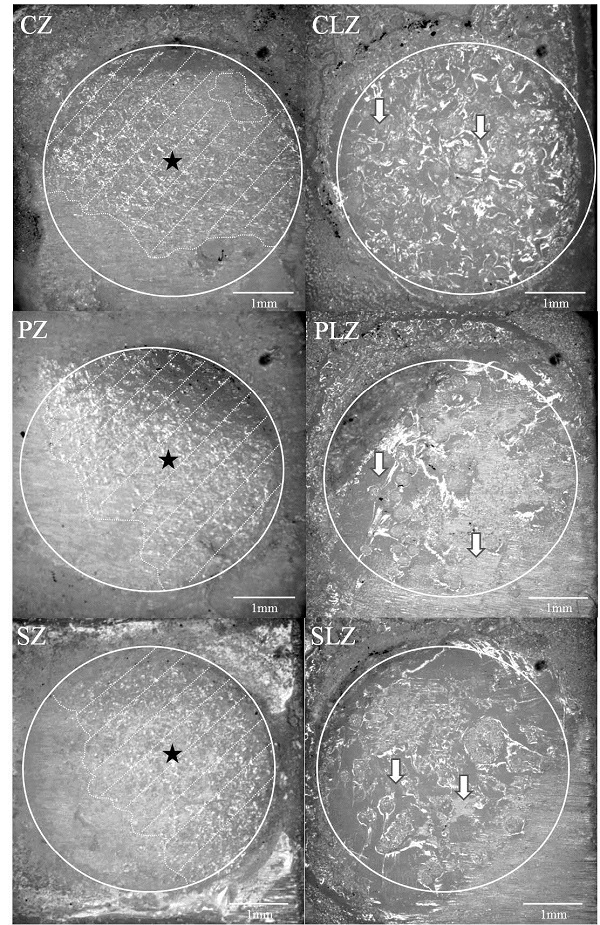

Figure 3 shows the fracture surfaces after the experiment on the shear bond strength of YTZ core and veneer ceramic. With regard to the fracture pattern of the ZP group, a crack that began within the veneer ceramic progressed toward the bonded surface, thereby breaking this surface. The bonded surface suffered from mixed failure, in which the YTZ core was partially exposed and the veneer ceramic particles remained. The ZLP group exhibited failure of cohesion between the liner and veneer ceramic in all the specimens.

View of a debonded veneered ceramic specimen. Stars indicate remaining intermediate ceramics, namely, area of Mixed failure; composite failure (cohesive/adhesive failure). Arrows indicate intermediate ceramics in the specimens is atypical distribution over a round, area of internal failure of the veneer ceramic; failure of the bonded area occurring due to the separation of the bonded layer.

A. Failure of the bonded area resulting from the separation of the surface of the boundary between the YTZ core and veneer ceramic.

B. Internal failure of the veneer ceramic; failure of the bonded area occurring due to the separation of the bonded layer.

C. Mixed failure; composite failure (cohesive/adhesive failure) of B or A [25]

DISCUSSION

The use of all-ceramic crowns as aesthetic restoration tools is expected to increase. Nevertheless, a considerable problem with all-ceramic crowns is chipping that may take place as they are used. The interface between YTZ core and veneer ceramic is known to be the weakest area of a crown. Success with restoration is expected to differ depending on the formation of a stable bond between YTZ core and veneer ceramic (Sundh and Sjögren, 2004; Dündar et al., 2007).

This study was conducted to examine the effects of surface roughness physically created on YTZ before sintering, and those of liner treatment on the strength of bonding between YTZ and veneer ceramic. The milling of YTZ core is performed under pre-sintering conditions, after which no additional milling, removal, or sandblasting should be necessary. The elimination of further treatments is important because post-sintering processing triggers local stress and heat generation on the YTZ core surface, thereby resulting in low-temperature degradation (Swab, 1991). Low-temperature degradation causes the tetragonal phase within YTZ core to transition into a monoclinic phase. Such phenomenon occurs under the conditions discussed below.

The aforementioned change is most active at a temperature of 200 to 300 °C and accelerates under the presence of moisture or vapor. Tetragonal (t)–monoclinic (m) phase transformation starts at the surface and progresses to the center, thereby creating micro and macro cracks. Even though certain compensation is possible by transformation toughing, the increase in monoclinic content reduces the strength, brittleness, and density of YTZ core (Kosmač et al., 1999).

Despite these findings, many researchers performed specimen cutting and continuous grinding after sintering in producing YTZ core. These methods can result in experimental inaccuracies by bringing about structural changes in the YTZ core surface. For such reason, the current work proceeded with YTZ core production and grinding processes in the pre-sintering state and did not trigger stress on the surface of the material after sintering.

Physical surface roughness was formed on YTZ core using a grinding tool. Its post-sintering surface roughness was higher than those of the PZ (3.08±0.58 μm), CZ (1.92±0.41 μm), and SZ (1.10±0.76 μm) groups; the difference was statistically significant (p<0.05). Such difference in surface roughness is attributed to the dispersion of particles by the grinding tool and to the differences in binder components (JEFFERIES and Steven, 1998).

Aboushelib et al (2005), Saito (2010), and Ozkurt (2010) reported that the bond strength and failure pattern of YTZ core and veneer ceramic are affected by airborne particle abrasion or liner use. Guazzato et al (2005) noted that airborne particle abrasion increased the mechanical bond of the YTZ core surface, and Fischer et al (2008) asserted that airborne particle abrasion didnot influence bond strength. As for liner application, Aboushelib et al (2006) observed that when a liner was used for core masking, the wettability of veneer ceramic and bond strength increased. By contrast, Tinschert et al (2000) reported that a liner weakened bond strength. Accordingly, the present research analyzed the shear bond strength of YTZ core and veneer ceramic by using six specimens with different surface roughness and liner treatment. The results show that the shear bond strength of the CZ group polished with the carborundum stone point was the highest (38.56±2.09 MPa) and was significantly different from those of the other experimental groups (p<0.05).

The comparison of the groups indicates that the ZP group showed high bond strength that was significantly different from those of the other groups (p<0.05). No statistically significant differences in shear bond strength were found among the SLZ, PLZ, and CLZ specimens in the ZLP group (p>0.05). These findings show that YTZ core and veneer ceramic were dependent on physical bonding rather than on chemical bonding; these results also verify that surface roughness treatment before sintering is a useful process for increasing the strength of bonding between YTZ core and veneer ceramic. In addition, liner application only minimally increased shear bond strength. The liner sprayed onto the YTZ surface served as coating that was also unaffected by surface roughness.

In terms of correlation between the results on surface roughness and shear bond strength, the surface roughness of the PZ group was higher than that of the CZ and SZ groups, but the shear bond strength of the CZ specimens was higher than those of the other groups. This result is attributed to the fact that the increase in bond surface area between YTZ core and veneer ceramic improved bond strength, or to the fact that excessive surface treatment not only concentrated stress on the bonded area thereby decreasing bond strength. Adequate surface roughness is a crucial element to raising bond strength (Anusavice et al., 1980).

Moreover, surface roughness may occur by volume contraction during YTZ core sintering. Additional research on this issue is necessary.

The width of the tip of the shear knife used to measure shear bond strength in the experiments was 0.5 mm. To deliver load to the bonded surface between the YTZ core and veneer ceramic, the shear knife was placed as close as possible to the YTZ core, but given the thickness of the shear knife, stress inside the ceramic could not be prevented. Here, when the strength of bonding between YTZ core and veneer ceramic was higher than the fracture strength of the latter, fracture began within the veneer ceramic (cohesive failure); when the strength of bonding between YTZ core and veneer ceramic was lower than the fracture strength of the latter, separation between the YTZ core and veneer ceramic occurred (adhesive failure). When observed by the naked eye, the fracture of the ZP group started within the veneer ceramic and then cracking progressed toward the bonded surface, thereby breaking this surface. This result is due to the fact that the strength of bonding between YTZ core and veneer ceramic was higher than the fracture strength of the latter; fracture was therefore initiated within the veneer ceramic. As indicated by the optical microscopic observation of the fractured surface, YTZ core was partially exposed and veneer ceramic particles remained on the bonded surface where separation occurred. The widest area of veneer ceramic was observed in the CZ group under the ZP group, followed by the PZ and SZ groups. Unlike the ZP group, the ZLP group exhibited veneer ceramic of irregular form. This result is attributed to the failure in cohesion between the liner and veneer ceramic.

Thus far, experimental standards or results on appropriate bond strength have not been determined (White et al., 2005). Nonetheless, recommendations regarding dental materials are determined on the basis of experimental research results on their mechanical properties. Many experiments have been conducted on the strength of shear bonding between YTZ core and veneer ceramic under different all-ceramic crown systems. An all-ceramic crown system should enable restoration with mechanical strength sufficient to resist bite and masticatory forces. Dundar et al (2007) and Al-Dohan et al (2004) reported that 23 to 41 MPa and 22 to 31 MPa, respectively, were commercially usable shear bond strengths for all-ceramic crown systems. The bond strength of YTZ core and veneer ceramic achieved in the current work is similar to previously published findings.

The CZ group had the highest bond strength, but the ZLP also exhibited bond strength that is sufficient for application in all-ceramic crown systems. On the basis of this finding, the strength of bonding between YTZ core and veneer ceramic was more strongly affected by physical surface treatment. For more valid results, there is a need to conduct further studies to identify the fracture between YTZ core and veneering ceramic as well as within the veneering ceramic, and to examine residual components on the fracture surface after fracture.

Conclusion

Within the limitations of the present study, the following conclusions could be reached:

1. Increased surface roughness of YTZ did not enhance shear strength.

2. Application of a liner did not enhance shear strength.

3. YTZ core and veneer ceramic were dependent on physical bonding rather than on chemical bonding.

Notes

References

-

MN Aboushelib, N De Jager, CJ Kleverlaan, AJ Feilzer, Microtensile bond strength of different components of core veneered all-ceramic restorations, Dent Mater, (2005), 21(10), p984-991.

[https://doi.org/10.1016/j.dental.2005.03.013]

- MN Aboushelib, M de Kler, JM van der Zel, AJ Feilzer, Effect of veneering method on the fracture and bond strength of bilayered zirconia restorations, International Journal of Prosthodontics, (2008), 21(3), p237-240.

- MN Aboushelib, CJ Kleverlaan, AJ Feilzer, Microtensile bond strength of different components of core veneered all-ceramic restorations: Part II: Zirconia veneering ceramics, Dent Mater, (2006), 22(9), p857-863.

-

M Albakry, M Guazzato, MV Swain, Fracture toughness and hardness evaluation of three pressable all-ceramic dental materials, J Dent, (2003), 31(3), p181-188.

[https://doi.org/10.1016/S0300-5712(03)00025-3]

-

HM Al-Dohan, P Yaman, JB Dennison, ME Razzoog, BR Lang, Shear strength of core-veneer interface in bi-layered ceramics, J prosthet Dent, (2004), 91(4), p349-355.

[https://doi.org/10.1016/j.prosdent.2004.02.009]

-

KJ Anusavice, PH Dehoff, CW Fairhurst, Materials Science Comparative Evaluation of Ceramic-metal Bond Tests Using Finite Element Stress Analysis, Journal of dental research, (1980), 59(3), p608-613.

[https://doi.org/10.1177/00220345800590030901]

- N De Jager, P Pallav, AJ Feilzer, The influence of design parameters on the FEA-determined stress distribution in CAD–CAM produced all-ceramic dental crowns, Dent Mater, (2005), 21(3), p242-251.

-

T Derand, M Molin, K Kvam, Bond strength of composite luting cement to zirconia ceramic surfaces, Dent Mater, (2005), 21(12), p1158-1162.

[https://doi.org/10.1016/j.dental.2005.02.005]

- M Dündar, M Özcan, B Gökçe, E Çömlekoğlu, F Leite, LF Valandro, Comparison of two bond strength testing methodologies for bilayered allceramics, Dent Mater, (2007), 23(5), p630-636.

-

J Fischer, B Stawarczyk, CHF Hämmerle, Flexural strength of veneering ceramics for zirconia, J dent, (2008), 36(5), p316-321.

[https://doi.org/10.1016/j.jdent.2008.01.017]

-

M Guazzato, L Quach, M Albakry, MV Swain, Influence of surface and heat treatments on the flexural strength of Y-TZP dental ceramic, J Dent, (2005), 33(1), p9-18.

[https://doi.org/10.1016/j.jdent.2004.07.001]

- JEFFERIES, R Steven, The art and science of abrasive finishing and polishing in restorative dentistry, Dental Clinics of North America, (1998), 42(4), p613-627.

- T Kosmač, C Oblak, P Jevnikar, N Funduk, L Marion, The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic, Dent Mater, (1999), 15(6), p426-433.

- R Luthardt, A Weber, H Rudolph, C Schöne, S Quaas, M Walter, Design and production of dental prosthetic restorations: basic research on dental CAD/CAM technology, Int J Comput Dent, (2001), 1.5(2-3), p165-176.

- RG Luthardt, M Holzhüter, O Sandkuhl, V Herold, JD Schnapp, E Kuhlisch, M Walter, Reliability and properties of ground Y-TZP-zirconia ceramics, J Dent Res, (2002), 81(7), p487-491.

-

PF Manicone, IP Rossi, L Raffaelli, An overview of zirconia ceramics: basic properties and clinical applications, Journal of Dentistry, (2007), 35(11), p819-826.

[https://doi.org/10.1016/j.jdent.2007.07.008]

- Z Ozkurt, U Iseri, E Kazazoglu, Zirconia ceramic post systems: a literature review and a case report, Dent Mater J, (2010), 29(3), p233-245.

-

A Saito, F Komine, MB Blatz, H Matsumura, A comparison of bond strength of layered veneering porcelains to zirconia and metal, The Journal of prosthetic dentistry, (2010), 104(4), p247-257.

[https://doi.org/10.1016/S0022-3913(10)60133-3]

- A Sundh, G Sjögren, A comparison of fracture strength of yttrium‐oxide‐partially‐stabilized zirconia ceramic crowns with varying core thickness, shapes and veneer ceramics, J Oral Rehabil, (2004), 31(7), p682-688.

- A Sundh, GA Sjögren, Comparison of fracture strength of yttrium‐oxide‐partially‐stabilized zirconia ceramic crowns with varying core thickness, shapes and veneer ceramics, J Oral Rehabil, (2004), 31(7), p682-688.

-

JJ Swab, Low temperature degradation of Y-TZP materials, Journal of materials science, (1991), 26(24), p6706-6714.

[https://doi.org/10.1007/BF00553696]

- J Tinschert, G Natt, W Mautsch, H Spiekermann, KJ Anusavice, Marginal fit of alumina-and zirconia-based fixed partial dentures produced by a CAD/CAM system, Oper Dent, (2000), 26(4), p367-374.

- SM Wegner, M Kern, Long-term resin bond strength to zirconia ceramic, J Adhes Dent, (2000), 2(2), p139-147.

-

SN White, VG Miklus, EA McLaren, LA Lang, AA Caputo, Flexural strength of a layered zirconia and porcelain dental all-ceramic system, system. J prosthet Dent, (2005), 94(2), p125-131.

[https://doi.org/10.1016/j.prosdent.2005.05.007]