Effects of Zero Suck-back Control Box (ZSCB) on prevention of external contaminants suction by various handpieces

Abstract

The dental high-speed air turbine handpiece operates by rotating the impeller inside the handpiece with compressed air. However, even if the inflow of the powered compressed air is stopped, the impeller rotates due to inertial rotation and creates negative pressure inside the handpiece (backflow suction, commonly known as suck-back). Organic matter and microorganisms in the patient’s oral cavity flow into not only the inside of the handpiece but also other parts connected to the handpiece, causing contamination.

In this study, the Zero Suck-back Control Box (ZSCB) device, which was developed to prevent the reverse suction of the handpiece, was applied to five different handpieces and tested. After driving the five different handpieces with or without ZSCB in the air, the presence or absence of suck-back was observed when they were stopped. In addition, when the handpiece was driven using the fluorescent solution to imitate the oral environment, the fluorescent solution flowing into the inside due to the reverse suction phenomenon was observed. It was evident that operating different handpieces with the ZSCB is effective in preventing the inhalation of external contaminants. In two different experiments conducted in this study, the use of ZSCB was shown to be effective in preventing regurgitation in both atmospheric and immersion conditions.

초록

치과용 고속 공기터빈 핸드피스는 압축공기로 핸드피스 내부의 임펠러가 회전하면서 작동하지만 동력이 되는 압축공기의 유입을 멈추더라도 관성회전으로 인해 임펠러가 회전하며 핸드피스 내부에 음압이 생기며(역류흡인) 환자 구강의 유기물과 미생물이 핸드피스 내부뿐만 아니라 핸드피스와 연결된 다른 부분에도 유입되어 오염의 원인이 된다. 본 연구에서는 핸드피스의 역류흡인 현상을 방지하고자 개발된 Zero Suck-back Control Box(ZSCB) 장치를 서로 다른 다섯 개 핸드피스에 적용하여 시험하고자 하였다. 대기중에서 서로 다른 다섯 개 핸드피스에 ZSCB를 적용 또는 적용하지 않고 구동한 후 멈추었을때 역류흡인 현상의 유무를 관찰하였다. 또한 구강 내 환경을 모방하기위해 형광용액을 사용하여 핸드피스를 구동했을때 핸드피스 역류흡인 현상으로인해 내부로 유입되는 형광용액을 관찰하였다. 서로 다른 핸드피스를 ZSCB와 함께 작동한 결과, 외부 오염물질 흡입 현상을 방지하는 데 효과적이었다. 본 연구에서 수행한 두 가지 다른 실험에서 ZSCB의 사용은 대기 중 상태와 침지 상태 모두에서 역류흡입 현상을 예방하는 효과를 보였다.

Keywords:

Handpiece, Suck-back, Cross infection, Contamination키워드:

핸드피스, 역류 흡입, 교차 감염, 오염Introduction

A dental high-speed handpiece operates as an impeller inside the handpiece rotates by a compressed air supply. However, despite stopping the supply of compressed air, the impeller still rotates via inertial rotation resulting in negative pressure inside the handpiece chamber (2, 4-8, 13). Due to this negative pressure formed inside the handpiece chamber, organic substances and microorganisms in a patient’s mouth are sucked into the handpiece and other components, such as coupling or tubing (2-8, 13). This is called a suck-back phenomenon (1-8, 13).

Suck back phenomenon causes contamination of the handpiece, coupling, and dental unit tubing (2-8). CDC (Centers for Disease Control and Prevention) and ADA (Australian Dental Association) regulate that every handpiece is sterilized between each patient (9-10). Also, CDC demands flushing of both dental airline and waterlines for 20-30 seconds to prevent cross-contamination (9). However, a recent study revealed that even though the bacterial CFU decreased after flushing the waterline for 3 minutes, it was still higher than the recommended maximum level (11). Therefore, flushing airlines and waterlines to prevent cross-contamination is not enough. It is crucial to minimize the influx of external materials and prevent components such as tubing and coupling from being contaminated.

Numerous systems have already been developed to reduce the suck-back phenomenon, but most are limited to minimizing the suck-back, not eradicating it (5, 8). Recently, one company has developed a handpiece with ‘Zero Drawback.’ The handpiece from this company has succeeded in preventing the suck back of external contaminants in air or aerosols (13). This handpiece's price is relatively higher than the average market price. Therefore, dental practices have realistic and financial difficulties replacing their current handpieces with a particular branded one.

Not long ago, Dunamis dental in Korea invented the Zero suck-back control box (ZSCB) to inhibit the suck-back phenomenon irrelevant to handpiece brands. ZSCB inhibits the suck-back phenomenon via an offset of negative pressure inside the handpiece chamber by supplying additional compressed air through the exhaust line, cooling water line, and spray airline when a practitioner stops operating the handpiece by releasing the foot pedal. As extra air is supplied and the positive pressure is maintained until the handpiece impeller entirely stops, it further prevents the possibility of external contaminants permeating into the handpiece through microleakage. Hence, this study aims to investigate the efficacy of ZSCB in preventing suck-back phenomenon in high-speed handpiece.

Materials and Methods

1. Materials

In this study, five handpieces from different companies were selected, as shown in Table 1.

2. Installation of ZSCB

We have tested the suck-back phenomenon in situations with and without the operation of ZSCB of 5 different branded handpieces in two different statuses, referring to the previous study on the suck-back phenomenon (12). ZSCB are installed in accordance to the previous study (12) (Figure 1 and Figure 2).

3. Testing suck-back pressure of handpieces and ZSCB in air

We tested the suck-back pressure of 5 different handpieces with and without the operation of ZSCB.

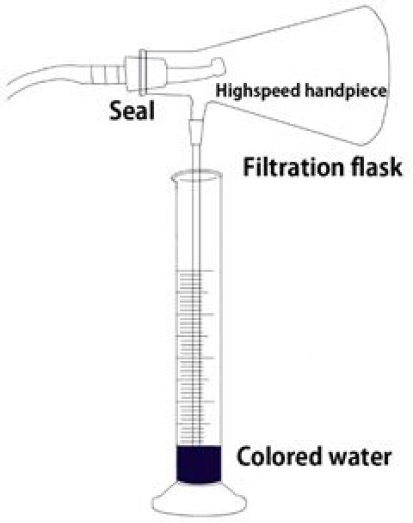

With the handpiece head inside the filtration flask, the opening of the filtration flask was tightly sealed with a rubber seal. A glass tube was connected to the arm of the filtration flask with silicone. The other end of the glass tube was placed in a 300 ml graduated cylinder filled with dark blue ink water. Each handpiece was rotated for 5 seconds with and without the operation of the ZSCB and stopped. All experiments were video recorded (4 K, 60 fps), and the highest height of water drawn to the glass tube was measured. For each handpiece, the test was repeated five times with ZSCB and another five times without ZSCB (Figure 3).

4. Foreign substance influx test depending on the operation of ZSCB

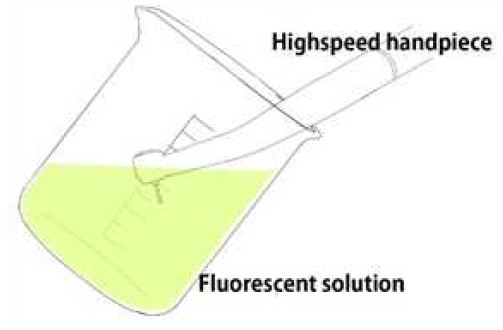

To observe whether foreign substances, such as saliva or blood in the oral cavity, are drawn into the handpiece, a fluorescent solution was used as a substitute for visibility.

With water-soluble fluorescent material (WB-402UV, Flamak Chemical Industry GMBH, Germany) and distilled water, a 10% 100 mL fluorescent solution was prepared. With and without operating the ZSCB, a handpiece with blank bur was run for 5 seconds and stopped while half of the handpiece head was immersed in the fluorescent solution. After halting the handpiece, the handpiece head remained in the fluorescent solution for 3 seconds and was then removed (Figure 3). With an 83% ethanol swab, the surface of the handpiece was thoroughly cleaned. Then, after dismantling the handpiece head, a retrieved handpiece cartridge was observed under the fluorescent stereoscope (Axio Zoom V16, Carl Zeiss, 6.5x, brightfield, UV-GFP). The above procedures were repeated using a new handpiece cartridge. The test was performed 50 times in total, five times for each manufacturer with/without the operation of ZSCB (Figure 4).

Results

1. Test of suck-back pressure of handpieces and ZSCB in air

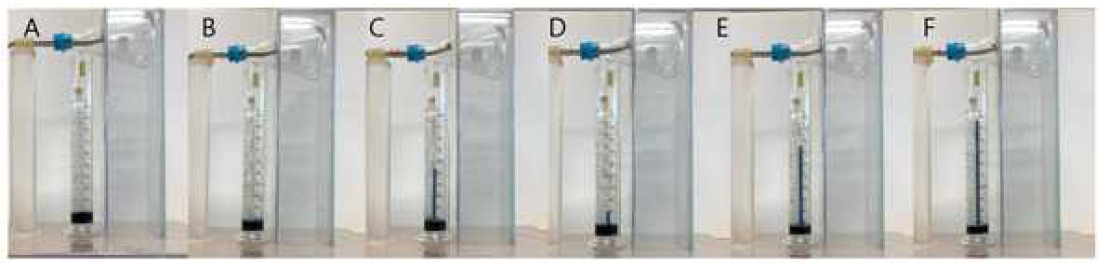

In all handpieces, except for handpiece A, the suck-back phenomenon was observed when run without the operation of ZSCB. When judged by the height of the water drawn into the glass tube, the degree of suck back increased in the order of C, B, D, and E. When ZSCB was operated, no water drawn into the glass tube by suck back phenomenon was noted in all handpieces (Table 2 and Figure 5).

2. Test of fluorescent solution influx while immersed.

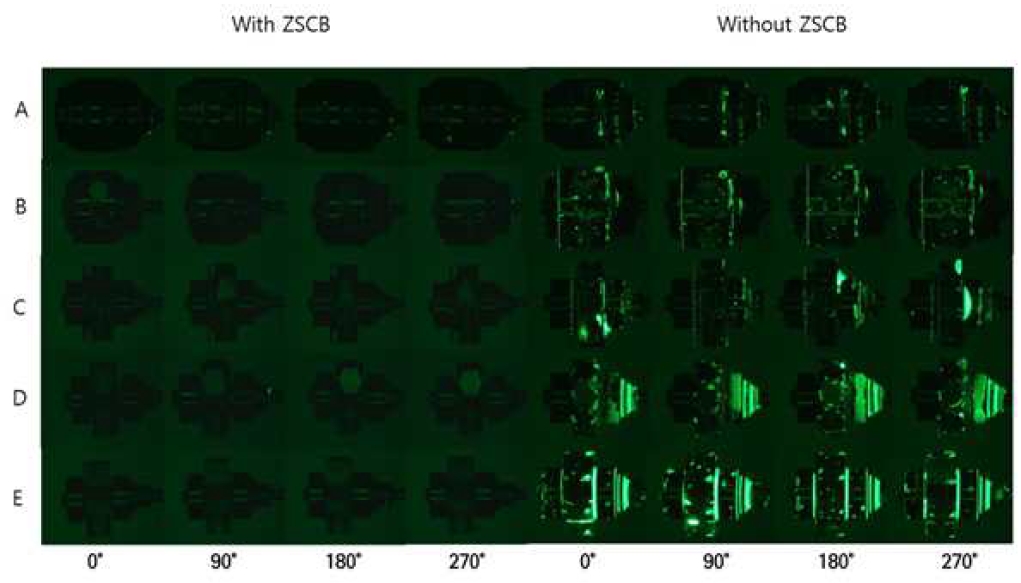

When run without the operation of ZSCB, the influx of fluorescent solution was observed in all handpiece cartridges. In housing-type handpiece cartridges such as handpiece A and B a small amount of fluorescent solution is observed even when run with the operation of ZSCB from where the positive air is unable to reach due to the design. When the ZSCB was not operated, fluorescent solution penetration to the cartridge’s impeller was observed in all experimental groups (Figure 6).

Discussion

This study observed the degree of suck-back phenomenon and influx of fluorescent solution when immersed in air turbine highspeed handpieces. From the experiment in air, when run without operating the ZSCB, we observed suck back phenomenon in all experimental groups but A. When ZSCB was operated while running the handpieces, no suck-back phenomenon was observed in all experimental groups.

Handpiece head immersed in patients' body fluid such as saliva or blood frequently happens in the clinical environment. To imitate this feasible environment, we carried out experiments while half of the handpiece head was immersed in the fluorescent solution, the solution being used to replace patients' body fluids. As a result of the experiment, the inflow of fluorescent solution was observed in all handpieces when ZSCB was not operated. This result is similar to some previous studies (5, 8, 13). When ZSCB was used, there was no trace of a fluorescent solution except for housing-type handpieces. However, a small quantity of the fluorescent solution was detected from housing-type handpieces (A, B) even when ZSCB was operated. Although notably different compared to those run without the operation of ZSCB, this could be due to the structural design of the housing type handpieces, as the part where the fluorescent solution was detected comes in direct contact with the fluorescent solution itself and positive air of ZSCB does not reach.

In the case of handpiece A, there was no observable ink-water uptake in the glass tube even when run without operating ZSCB. However, a small amount of fluorescent dye was noted from the handpiece impeller when tested with half of the handpiece head immersed in the fluorescent solution. From the microscopic image, in handpiece A, the amount of fluorescent solution inflow was different from that of the impellers of other handpieces. Therefore, whether the fluorescent solution found on handpiece A resulted from the suck-back phenomenon or pervaded through the microscopic gap remains controversial.

The dental air turbine highspeed handpiece is contaminated during the treatment, not only the external parts via direct contact but also the internal parts due to the suck-back phenomenon and retraction (1-8, 12). Therefore CDC and ADA mandate practitioners to clean and sterilize handpieces with appropriate measures after each use (9-10). According to research, contamination of handpieces is not limited to handpieces but also includes couplings, water lines, air lines, etc. Even if the handpiece is replaced with a sterilized one for each patient, due to the contaminated tubings, there is a possibility of infection among dental workers due to aerosol generated by the handpiece (16, 17) as well as cross-infection between patients (2-8, 12). The CDC requires that the water and air lines be flushed for 20-30 seconds per patient to prevent cross-infection between patients(9). However, flowing down the water lines and the air lines for 30 seconds is not sufficient to remove all contamination from each line (4, 11, 13), and it takes at least 4-7 minutes to remove the contamination altogether (4, 13). In order to prevent contamination of the dental unit water line due to the contraction of the handpiece, the international standard ISO 7494-2 stipulates that the amount of retraction of the dental unit procedural water or solution for treatment should not exceed 40 mm3 (=0.04 ml) (18). It is required to provide an explanatory statement that only instruments with retraction prevention devices should be used if the dental chair unit cannot prevent the backflow of the treatment water due to retraction (19).

As observed experimentally, the possibility of cross-infection can be reduced by using handpieces and devices that prevent suck-back. Several manufacturers have developed and commercialized products that avoid the suck-back phenomenon of the handpiece (5, 8, 13), but there is no standard in this regard. Since there is a risk of cross-infection due to the suck-back of the handpiece, it is necessary to establish a standard to prevent cross-infection due to suck-back. Yet, even though the inside of the handpiece is not contaminated when the suck-back phenomenon does not occur, wiping the surface of the handpiece with a disinfectant such as 70 % alcohol does not entirely kill bacteria (1, 14, 15), so autoclaving the handpiece is still essential.

In this experiment, we observed whether the fluorescent solution was introduced by observing the cartridge inside the handpiece head. There is a possibility that a part can be overlooked even when observing under the fluorescent stereoscope. Further studies are required as bacterial culture tests may be more accurate to investigate whether contamination is wholly prevented. The experiment was conducted by changing the cartridge inside the handpiece to a new one. The amount of fluorescent solution detected in the cartridge increased according to the progress of the experiment in a specific experimental group. This can be seen as a result of the accumulation of fluorescence solution in tubings that are not visible as the experiment proceeds. In order to obtain accurate results, it is considered advisable to replace the handpiece after each cycle.

Conclusions

When operated with ZSCB, different handpieces effectively prevented external contaminants' suction. From two different experiments carried out in this study, the use of ZSCB showed its effectiveness in preventing the suck-back phenomenon in both the atmospheric environment and immersion state. Although lacking bacterial culture test to fully assess its efficacy in infection control, based on tests carried out, ZSCB can be used as one of the methods to prevent the suck-back phenomenon, thus contributing to avoiding cross-contamination in clinical situations. In addition, future research should further develop and confirm these findings by conducting bacterial culture tests.

References

- Masuda K, Ohta M, Ohsuka S, Matsuyama M, Ashoori M, Usami T,et al. Bacteriological evaluation of a new air turbine handpiece for preventing cross-contamination in dental procedures. Nagoya J Med Sci. 1994;57(1-4):69-76.

-

Ojajärvi J. Prevention of microbial contamination of the dental unit caused by suction into the turbine drive air lines. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 1996;81(1):50-2.

[https://doi.org/10.1016/S1079-2104(96)80147-8]

-

Petti S, Moroni C, Messano GA, Polimeni A. Detection of oral streptococci in dental unit water lines after therapy with air turbine handpiece: biological fluid retraction more frequent than expected. Future Microbiol. 2013;8(3):413-21.

[https://doi.org/10.2217/fmb.12.151]

-

Checchi L, Montebugnoli L, Samaritani S. Contamination of the turbine air chamber: a risk of cross infection. J Clin Periodontol. 1998;25(8):607-11.

[https://doi.org/10.1111/j.1600-051X.1998.tb02495.x]

-

Montebugnoli L, Dolci G. Effectiveness of two devices designed to prevent fluid retraction in a high-speed handpiece. J Prosthet Dent. 2000;84(2):225-8.

[https://doi.org/10.1067/mpr.2000.108414]

-

Cicciù M. Water Contamination Risks at the Dental Clinic. Biology (Basel). 2020;9(3):43.

[https://doi.org/10.3390/biology9030043]

-

Artini M, Scoarughi GL, Papa R, Dolci G, De Luca M, Orsini G, et al. Specific anti cross-infection measures may help to prevent viral contamination of dental unit waterlines: a pilot study. Infection. 2008;36(5):467-71.

[https://doi.org/10.1007/s15010-008-7246-5]

- Toomarian L, Rikhtegaran S, Sadighi M, Savadi Oskoee S, Alizadeh Oskoee P. Contamination of dental unit water and air outlets following use of clean head system and conventional handpieces. J Dent Res Dent Clin Dent Prospects. 2007;1(1):43-7.

-

Kohn WG, Collins AS, Cleveland JL, Harte JA, Eklund KL, Malvitz DM. Guidelines for infection control in dental health-care settings. J Am Dent Assoc. 2004;135 (1):33-47.

[https://doi.org/10.14219/jada.archive.2004.0019]

- Australian Dental Association. Guidelines for Infection Control. 3rd ed. Australian Dental Association; 2015.

-

Alkhulaifi MM, Alotaibi DH, Alajlan H, Binshoail T. Assessment of nosocomial bacterial contamination in dental unit waterlines: Impact of flushing. Saudi Dent J. 2020;32(2):68-73.

[https://doi.org/10.1016/j.sdentj.2019.07.003]

-

Ozawa T, Nakano M, Arai T. In vitro study of anti-suck-back ability by themselves on new high-speed air turbine handpieces. Dent Mater J. 2010;29(6):649-54.

[https://doi.org/10.4012/dmj.2010-008]

-

Lewis DL, Boe RK. Cross-infection risks associated with current procedures for using high-speed dental handpieces. J Clin Microbiol. 1992;30(2):401-6.

[https://doi.org/10.1128/jcm.30.2.401-406.1992]

- Ohsuka S, Ohta M, Masuda K, Kaneda T, Ueda M. Microbiological evaluation of a newly designed dental air-turbine handpiece for anti-cross contaminations. Int J Prosthodont. 1994;7(3):201-8.

-

Pinto FM, Bruna CQ, Camargo TC, Marques M, Silva CB, Sasagawa SM, Mimica LM, Graziano KU. The practice of disinfection of high-speed handpieces with 70% w/v alcohol: An evaluation. Am J Infect Control. 2017;45(1):e19-e22.

[https://doi.org/10.1016/j.ajic.2016.08.004]

-

Leggat PA, Kedjarune U. Bacterial aerosols in the dental clinic: a review. Int Dent J. 2001 Feb;51(1):39-44.

[https://doi.org/10.1002/j.1875-595X.2001.tb00816.x]

-

Ionescu AC, Cagetti MG, Ferracane JL, Garcia-Godoy F, Brambilla E. Topographic aspects of airborne contamination caused by the use of dental handpieces in the operative environment. J Am Dent Assoc. 2020;151(9):660-667. 7494-2:2022(en)

[https://doi.org/10.1016/j.adaj.2020.06.002]

- International Organization for Standardization. ISO 7494-2:2022(en)Dentistry — Stationary dental units and dental patient chairs — Part 2: Air, water, suction and wastewater systems. Geneva: ISO; 2022.