Effect of coloring treatment of translucent zirconia on the masking ability of metal abutment

Abstract

Translucent monolithic zirconia is widely used because it has continuously enhanced color and translucency. However, when translucent monolithic zirconia are used for esthetic zone like anterior, it has problem to be exposed to color of titanium abutment. The purpose of this study was to evaluate the effect of coloring and cementing of translucent zirconia on the color masking of titanium abutments. The CIE L*, a*, and b* values were measured using a spectrophotometer in three subgroups after coloring with A2 colorant and white opaque colorant, and the color difference and translucency of each group were analyzed. In the A2 colorant application group, the color difference (ΔE*) between zirconia and zirconia on titanium abutments was not clinically acceptable (ΔE*>3.3). In the white opaque group and the white opaque plus A2 colorant group, the color difference (ΔE*) between zirconia and zirconia on titanium abutments was clinically acceptable (1<ΔE*<3.3). The translucency of zirconia was significantly affected by the coloring treatment (P<.001). The Pearson correlation between color difference and translucency parameters was high (r=0.982, R2=0.965). The white coloring treatment to translucent zirconia affected masking of titanium abutment. The combination of A2 colorant and white opaque colorant increased the color masking effect of titanium abutments and achieved a shade similar to natural teeth. Resin cement adhesion to translucent zirconia did not affect the color masking of titanium zirconia. As the zirconia translucency increases, it had less of an effect on the titanium abutment.

초록

반투명 단일구조 지르코니아는 색상과 투명도가 지속적으로 향상되어 널리 사용되고 있다. 하지만 전치와 같은 심미 부위에 반투명 단일구조 지르코니아를 사용할 경우, 티타늄 지대주의 색상이 노출되는 문제가 있다. 본 연구의 목적은 반투명 지르코니아의 착색처리와 시멘트가 티타늄 지대주의 색차단에 미치는 효과를 평가하는 것이다. A2 착색제와 화이트 오펙 착색제로 착색처리 후 세 가지의 하위그룹으로 나누어 분광측색계를 사용하여 CIE L*, a*, b* 값을 측정하였으며 각 그룹별 색차와 반투명도를 분석하였다. A2 착색제 도포시, 반투명 지르코니아 시편과 티타늄 지대주에 반투명 지르코니아를 위치한 시편 간의 색차 (ΔE*)는 임상적으로 수용할 만한 역치값보다 높은 색상 변화를 보였다(ΔE*>3.3). A2 착색제만 도포하거나 화이트 오펙과 A2 착색제를 함께 도포시, 반투명 지르코니아 시편과 티타늄 지대주에 반투명 지르코니아를 위치한 시편 간의 색차 (ΔE*)는 임상적으로 인지할 만한 색상 변화는 없었다 (1<ΔE*<3.3). 착색처리는 모든 지르코니아 시편 그룹의 반투명도에 유의한 영향을 미쳤다 (P<.001). 색차와 반투명도는 매우 높은 정적인 상관관계를 보였다 (r=0.982, R2=0.965). 반투명 지르코니아에 화이트 오팩 착색제 적용은 티타늄 지대주의 색차단에 효과가 있었다. A2 착색제와 화이트 오펙 착색제를 함께 적용할 시, 티타늄 지대주의 색차단 효과를 높이고 자연치와 유사한 색조를 얻을 수 있었다. 반투명 지르코니아에 레진시멘트의 접착은 티타늄 지대주의 색차단에 영향을 미치지 않았다. 지르코니아의 반투명도가 증가할수록 티타늄 지대주에 대한 색차단 효과는 적었다.

Keywords:

Translucent zirconia, Coloring treatment, Masking ability, Metal abutment키워드:

반투명 지르코니아, 착색처리, 금속 지대주, 색차단Introduction

Recently, Various changes have been made in dental community to satisfy the esthetic as social awareness and interest have increased. In order to get a satisfactory color, the crown must reproduce the color of the natural teeth, which is one of the ultimate goals. However, the process of obtaining harmony of color is not easy due to the complex visual properties of teeth, with many factors to consider, such as the light source used to evaluate colors, structural properties of dental crown and teeth and surface (1). There is a difference in the perception of color depending on the individual and as a result, different standards for color differences are presented (2, 3). Finally, factors to consider in order to obtain the desired color and translucency of zirconia include the type and thickness of ceramics (4, 5), a coloring liquid (6), cement (7), and abutments (8). In particular, the color and translucency of zirconia can be significantly affected by the color of the crown depending on the type of substructures (9), so the problem of masking the color of these substructures should be considered.

Implants are widely used as one of the treatment methods that can recover oral health and esthetics by artificially restoring teeth when teeth are lost. Among the implant components, titanium, which palys the role of abutment, has excellent biocompatible and mechanical properties (10). However, the appearance of the soft tissue around the abutment can be affected by silvery white and opaque color of titanium abutment (11). Furthermore, esthetic can be more affected when titanium abutment is used in anterior zone (12) or ceramic is used to superstructure of it (13, 14). It has been reported that the masking of color of titanium abutment made a different result depending on the type (14) and thickness (8, 12) of ceramic.

The selection of material for bonding the teeth or implant abutment to the ceramic restoration is very important for lifetime of the ceramic restoration (15). Among the types of dental cement, resin cement is preferred for bonding zirconia restoration (16). The range of appropriate thickness for resin cement is 50 to 100 µm (17). When the size of the inner surface is larger than 120 µm, the resistance for fracture of ceramics decreases (18). Recently dual polymerizing self adhesive resin cement among various cements is commonly used (19), but Almeida et al (20) reported that the color stability is lack. Many studies have reported that the color and translucency of zirconia can be affected by resin cement (21-23). According to a study (7), the thickness of resin cement than the color of resin cement is more affected on the final color of zirconia. Therefore, the cement also needs to be carrefully selected for the best esthetics.

Zirconia, which has improved translucency with various coloring techniques, is continuosly expanded its usable range in dentistry (24). The color and translucency of zirconia have shown different result depending on various methods of applying the coloring liquid, such as whether or not the coloring liquid is applied (25), Acid or water (26), and the number of times of application (27). Although color can be given in advance in the process of producing zirconia, precolored zirconia produced in this way may be insufficient to reproduce the color of natural teeth by itself (28). Application of coloring liquid to zirconia can give an esthetically better result by adding a color that looks more like natural teeth (25, 29), so it needs to be used appropriately.

The translucency and color of zirconia are rapidly developing from blocks with diverse translucency to multi-layered zirconia recently. As the translucency of zirconia increases, the influence of the implant substructure may increase on the final color of translucent zirconia (14). Cement and abutments which are essentially included in the implant system may affect the final color of translucent zirconia (8). When a monolithic zirconia restoration with high translucency is used as the superstructure of the implant system in clinical, the problem that color of titanium abutment is exposed have been constantly occured, so it must be able to properly mask it.

Currently, a variety of methods have been tried to solve this problem, but when translucent zirconia is used with titanium abutment, studies on method for effectively masking of color of it are lack.

The purpose of this in vitro study is to evaluate the effect of coloring treatment of translucent zirconia (A2 coloring liquid and white opaque coloring liquid) and cement on the masking of color of titatium abutment. The first null hypothesis is that the application of A2 coloring liquid to zirconia does not affect the masking of color of titatium abutment, and the second null hypothesis is that white opaque to zirconia does not affect the masking of color of titatium abutment. and the third null hypothesis is that the cement does not affect the masking of color of titanium abutment.

Materials and Methods

A 4 mol% translucent zirconia block (RAZOR 1100, UNC International, Seoul, Korea), A2 coloring liquid (Natural Liquid, UNC International, Seoul, Korea), white opaque coloring liquid (Esthetic liquid, Kuwotech, Gwangju, Korea), one color of resin cement (RelyX™ U200, 3M ESPE, St. Paul, MN, USA), and a titanium block (ARUM Premium Titanium, ARUM Dentistry, Daejeon, Korea) were used.

Zirconia specimens were designed as a cylinder with a size of 10 mm (diameter)×0.8 mm (thickness) using a CAD program (Autodesk Inventor 2021, Autodesk, San Francisco, CA, USA). A total of 32 translucent zirconia specimens were manufactured by cutting with a milling machine (Roland DWX-52D, DG Shape, Hamamatsu, Japan) considering the shrinkage of zirconia. On one side of the zirconia specimens, A2 coloring liquid and white opaque coloring liquid were applied. When both types of coloring liquid were applied, the A2 coloring liquid was first applied, and then the white opaque coloring liquid was additionally applied. The translucent zirconia specimens were classified into 8 groups according to the coloring treatment; non treatment group (N), A2 coloring liquid 1, 3, 6 times (C1, C3 C6), white opaque coloring liquid 1 time (W), white opaque coloring liquid 1 time after A2 coloring liquid 1, 3, 6 times (WC1, WC3, WC6) (n=4). Non-treatment specimens were used as control. There was no additional drying between the application of the A2 coloring liquid and the white opaque coloring liquid. All specimens applied with the coloring liquid were dried at room temperature for 5 min, dried in an oven at 80 ℃ for 30 min. It was put into a sintering furnace (LHT 02/17/LB; Nabertherm, Lilienthal, Germany) and sintered according to the sintering schedule recommended by the manufacturer. The sintered specimens were finally checked for size using a caliper (Digimatic Caliper, Mitutoyo, Kawasaki, Japan).

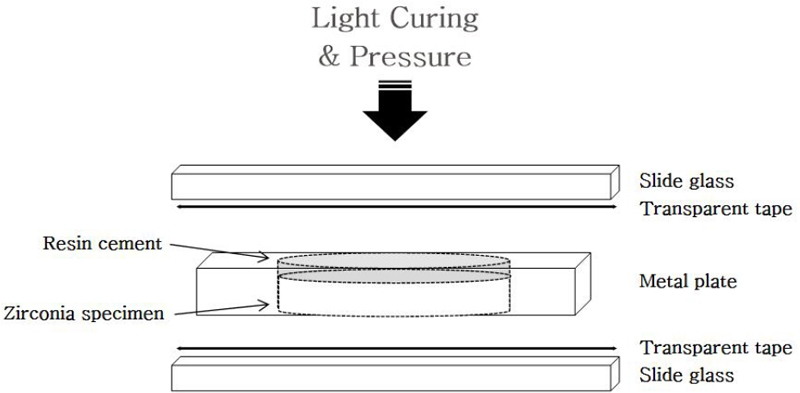

A metal plate with a diameter of 10 mm in the center and a circular hole in the size of 20×20×0.9 mm was manufactured using a milling machine (5X-500, ARUM Dentisty, Daejeon, Korea) to adhere the resin cement with a thickness of 0.1 mm to the zirconia specimen. To facilitate the separation of the specimen, vaseline was thinly applied to the hole of the metal plate, and a single layer of transparent tape was attached to one side of all slide glasses. All zirconia specimens were placed in the hole of the metal plate with the colored surface facing up, and the resin cement was mixed using a special tool according to the manufacturer's instructions, and then filled in the hole of the metal plate. A slide glass was placed thereon and a pressure of 1.5 kg was constantly applied for 10 sec. And it was light-cured for 20 sec using an LED light curing machine (LED Curing Light, DK Mungyo, Gimhae, Korea). When the photopolymerization was completed, the specimen was separated from the metal plate and slide glass, and the remaining resin cement was cleanly removed (Figure 1).

A cylindrical titanium specimen of 10 mm (diameter) × 5 mm (thickness) was prepared by cutting the titanium block with a milling machine (5X-500, ARUM Dentisty, Daejeon, Korea).

The color of the sintered zirconia specimens was measured by spectrophotometer (CM-3600A, Konica Minolta, Osaka, Japan). Before measuring the color for each group, the spectrophotometer was calibrated. The color of the zirconia specimen group (Z) was measured on a white plate (L*: 96.82, a*: 0.32, b*: 3.18) and the black plate (L*: 6.29, a*: 1.78, b*: -0.56) under the same conditions. The color was measured by placing a zirconia specimen on a titanium background (L*: 62.70, a*: 0.60, b*: 3.43)(ZT) and the color was measured by placing a zirconia specimen cemented with resin cement on a titanium background (ZRT). No intermediate was applied between each specimen (Table 1).

Classification of the zirconia specimens depending on the coloring treatment, resin cement and titanium abutment

The average value was calculated using the value obtained by measuring the center of the specimen 5 times for each specimen, a total of 20 times for each group. Colors were expressed in the CIE coordinate, a color standard established by the Commission Internationale de l'Eclairage, and the color difference (ΔE*) was calculated using the measured values according to the formula: ΔE*={(ΔL*)2+(Δa*)2+(Δb*)2}½, ΔL*=L*1–L*2, Δa*=a*1–a*2, Δb*=b*1–b*2, L* indicates brightness, +a* means red, –a* means green, +b* means yellow, and –b* means blue tends to be stronger. The threshold of color difference is considered undetectable by the human eye in the range of values less than 1, clinically acceptable in the range greater than 1 and less than 3.3, and clinically unacceptable in the range of value than more 3.3 (1). Translucency (TP) value was calculated according to the formula using the measured value: TP=[(ΔL)2+(Δa)2+(Δb)2]½, ΔL=LB –LW, Δa= aB –aW, Δb=bB –bW, the subscript B denotes the background of the black plate and the subscript W denotes the background of the white plate in the translucency formula. A translucency value of 0 means completely opaque and 100 means completely transparent (30).

A statistical software program (IBM SPSS Statistics, v26.0; IBM Corp, Chicago, IL, USA) was used for the experimental results, and the significance level for statistical significance was set to .05 (α=.05). The Kolmogorov-smirnov test was performed to test the normality of the data and Scheffé' test was performed. Multi-variate ANOVA and one-way ANOVA were performed to determine whether there was a significant difference in color and translucency between each group and subgroup according to the coloring treatment. Pearson correlation and linear regression were performed to analyze the correlation between translucency and color difference.

Results

All data followed a normal distribution. The CIE L*, a*, b of the translucent zirconia specimen (Z) according to the coloring treatment are shown (Tables 2). Coloring treatment significantly affected the CIE L*, a*, b* values of all zirconia groups (Z) (P<.001). In C group to which A2 coloring liquid was applied, the CIE L* value decreased, and the CIE a* and b* values increased as the number of applications increased. In group W to which white opaque coloring liquid was applied, CIE L* and b* values increased, and CIE a* values decreased as the number of applications increased.

The CIE L*, a*, b of the subgroups according to coloring treatment are shown in Table 3. The CIE L*, a*, and b* values between the Z group, the ZT group, and the ZRT group showed a significant difference according to the coloring treatment (P<.001). All ZT group showed significantly higher CIE L*, a*, b* values than that of Z group. When the A2 coloring liquid (C) was applied, the CIE L* values significantly decreased in the ZRT group than in the ZT group, and there was no significant difference in the CIE a* and b* values. When white opaque coloring liquid (W) was applied, the CIE L* values significantly decreased, and the CIE a* and b* values significantly increased in the ZRT group compared with the ZT group.

Means and standard deviations for CIE, L*, a*, b* value of subgroups of each group according to coloring treatment

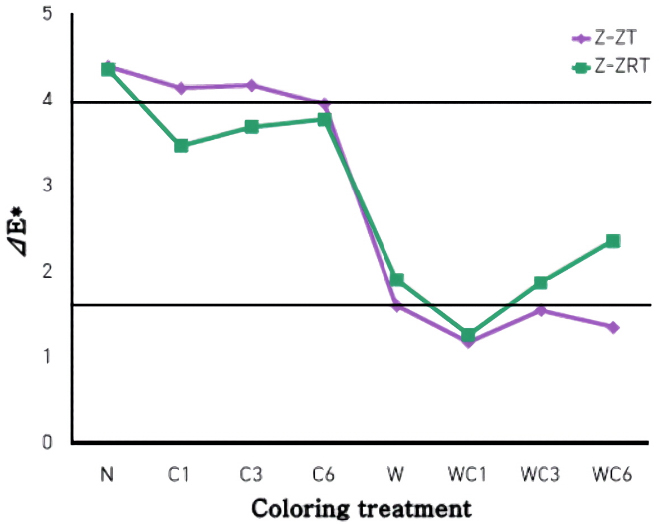

Figure 2 shows the color difference between zirconia group (Z), zirconia and titanium group (ZT), zirconia cemented with resin cement and titanium group (ZRT). The color differences between Z and ZT, and Z and ZRT in the WC1 group were the smallest at 1.17 and 1.89, respectively. The color differences between Z and ZT, and Z and ZRT in the N group were the largest at 4.38 and 4.35, respectively. In the N and C groups, the color differences between all Z and ZT, and Z and ZRT were greater than 3.3. In the W and WC groups, the color difference values between all Z and ZT, and Z and ZRT were in the range greater than 1 and less than 3.3. When resin cement was adhered to translucent zirconia, the color differences decreased in the N and C groups, but increased in the W and WC groups.

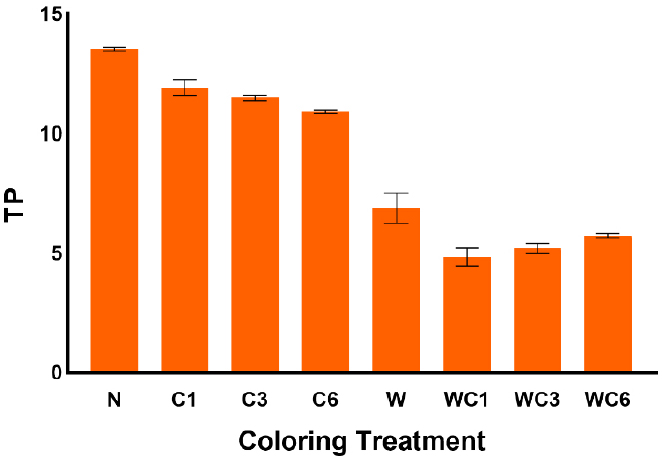

Translucency of Z group according to the coloring treatment was analyzed (Figure 3). The coloring treatment significantly affected on translucency of all Z groups (P<.001). The translucency of the zirconia specimen without coloring treatment (N) was the highest at 13.51. The translucency of the specimen applied one application of the white opaque coloring liquid after one application of the A2 coloring liquid (WC1) was the lowest at 4.84. In the group applied A2 coloring liquid (C), the translucency decreased as the number of times the coloring liquid was applied increased. The translucency of the group applied the white opaque coloring liquid (W) was 6.90, which was lower than that of the group applied the A2 coloring liquid. The translucency of the group applied with the A2 coloring liquid and the white opaque coloring liquid (WC) was lower than that of the group applied with the white opaque coloring liquid (W).

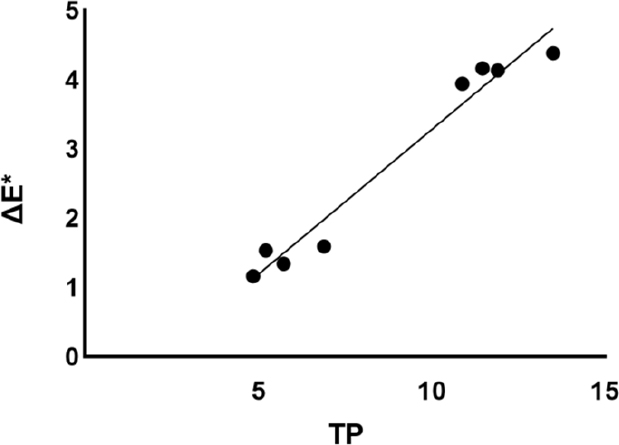

Correlation analysis was performed on the translucency of Z according to the coloring treatment and the color differences between Z and ZT groups (Figure 4). Color differences and translucency showed a very high positive correlation (r=0.982, R2=0.965).

Discussion

In this in vitro study, the white opaque coloring liquid effected on the masking of the color of titanium abutment, but the A2 coloring liquid and cement did not affect on the masking of the color of the titanium abutment. Therefore, the first null hypothesis that the application of A2 coloring liquid to zirconia does not affect the masking of color of titatium abutment was accepted. The second null hypothesis that application of white opaque to zirconia does not affect the masking of color of titatium abutment was rejected. The third null hypothesis that the cement does not affect the masking of color of titatium abutment was accepted.

Vichi et al (1) reported that it is very important to understand whether color difference can be perceived by the human eye or can be judged to be clinically relevant, but it is subjective and difficult to judge. Several studies have reported standards for color differences. Douglas et al (2) studied the range of perceived or acceptable color differences using artificial teeth. The value of color differences perceptible by 50% of observers was 2.6, and the value of color differences of 5.5, where the color inconsistency was detected by 50% of the observers, was clinically unacceptable. Ishikawa-Nagai et al (3) compared the color difference between anterior porcelain crowns and natural teeth. The threshold of the color differences was 1.6, and when the color differences was less than 1.6, it was considered that the human eye could not perceive it. Vichi et al (1) classified color differences into three ranges. In the range where the color difference value is less than 1, it can be considered imperceptible by the human eye, and in the range greater than 1 and less than 3.3, it was considered to be recognizable by a skilled technician and clinically acceptable. In the range greater than 3.3, it was considered perceptible by an unskilled person, such as a patient, and was not clinically acceptable. This study was based on the criteria of color differences suggested by Vichi et al (1).

In this in vitro study, when the color difference between the Z and ZT group decreased, the effect of masking of titanium abutment increased. It is shown that as the number of times of application of the A2 coloring liquid increases, the color difference between the Z and ZT groups decreases and the effect of masking of titanium abutment increases. However, the color difference was greater than 3.3 in all C groups applied A2 coloring liquid, which was not clinically acceptable. It is judged that the application of the A2 coloring liquid does not have effect of masking of titanium abutment. All W and WC groups applied with white opaque coloring liquid showed color differences within the clinically acceptable range (1<ΔE*<3.3). It is judged that the application of the white opaque coloring liquid to 0.8 mm zirconia is effective in masking of the titanium abutment. When A2 and White opaque coloring liquid are applied once, respectively, it shows the lowest color difference (ΔE*=1.16) and is shown most effective.

Bayindir and Koseoglu (23) reported that resin cement caused a color change, in particular, opaque resin had a greater effect on color than transparent resin. Chongkavinit and Anunmana (10) reported that 0.2 mm yellow and transparent resin cement was used, and the color of the cement did not affect the final color. In this in vitro study, when comparing the color difference between the Z group and ZT group, and the Z and ZRT group, in the C group applied the A2 coloring liquid the color differences decreased, and in the W and WC groups applied White opaque coloring liquid the color differences increased. It is judged that in the C group, the L* value of the ZRT group adhered with the resin cement was decreased compared with the ZT group, so the color differences with the Z group was relatively small. In the W and WC groups, the a* and b* values of the ZRT group adhered with resin cement increased than the ZT group, indicating that the color difference from the Z group was relatively large.

Vichi et al (7) studied the masking of color of carbon fiber, zirconia and white posts. When the thickness of the ceramic was 1 mm, all color differences between 0.1 mm and 0.2 mm of brown, yellow, and white cements were less than 1 (ΔE*<1). Dai et al (31) studied effect of masking color using color differences after zirconia with four thicknesses of 0.7, 1.0, 1.2, and 1.5 mm and eight colors of 1M1, 1M2, 2M1, 2M2, 2M3, 3M2, 4M2, and 5M2 adhered to dark, discolored, and metal substructure. Most of these zirconia specimens showed poor effect of masking of titanium abutment in the substructure of cobalt-chromium alloy (ΔE*>5.5), but the 1.5 mm thickness of zirconia specimens with the colors of 2M1, 2M3, 3M2, 4M2 and 5M2 were found to be within the clinically acceptable range of color differences regardless of the cement color (ΔE*<5.5). In this in vitro study, 0.8 mm zirconia and 0.1 mm resin cement were used. The color differences between all subgroups Z and ZT, and Z and ZRT before and after bonding resin cement were greater than 3.3 in N and C groups, and larger than 1 and smaller than 3.3 in the W and WC groups. According to this in vitro study, like the results of Vichi et al (7) and Dai et al (31), resin cement did not significantly effect on the masking of color of titanium abutment. Chongkavinit and Anunmana (10) reported that 0.2 mm resin cement and 1.5 mm and 2.0 mm ceramic could mask the color of titanium abutment (ΔE*≤3).

In this in vitro study, the color differences between the Z and ZT group increased as the translucency increased. As a result of Pearson correlation analysis, the translucency and the color differences between the Z and ZT groups found a very high static correlation. The higher the translucency, the larger the color differences and the smaller the effect of masking of color of the titanium abutment. As a result of the analysis of this study, when titanium abutment is used, the effect of making of color of the titanium abutment is expected to approach within the clinically acceptable color differences (ΔE*< 3.3) at a translucency value of about 10 or less. Wang et al (5) evaluated the translucency of glass ceramics with a thickness of 0.6 to 2.0 mm and zirconia with a thickness of 0.4 to 1.0 mm. The translucency ranges of glass ceramic and zirconia were 2.2 to 25.3 and 5.5 to 15.1, respectively, and the translucency decreased as the thickness increased. The 0.8 mm thickness of zirconia used in this study had a translucency of 13.51. In this in vitro study, it was found that translucency decreased according to the coloring treatment. When used for titanium abutment, ceramics with appropriate translucency and coloring treatment are expected to be effective in blocking the color of the underlying structure. When translucent zirconia is used for titanium abutment, ceramics with appropriate translucency and coloring treatment would effect on masking of color of substructure.

For the color of zirconia, Kim and Kim (28) studied the color according to various types of monolithic precolored zirconia. Different brands of ceramics marketed in the same A2 color showed significant differences in color and translucency values. When the precolored zirconia was restored, if the adjacent tooth was a different type of ceramic or natural tooth, the L* value was relatively high and the a* and b* values were low, indicating that the color difference could be seen. O'Brien et al (32) stated that the range of color of the natural teeth was 64.3 to 78 for L*, 2.6 to 2.8 for a*, and 9.9 to 25.7 for b*, respectively. As a result of Cho et al (33), the anterior region in the colorimeter, L* value is 39.0 to 65.8, a* value is –5.1 to –4.0, b* value is –1.0 to –15.1, and in Shade Visuon system, L* value is 64.5 to 83.2, a* value This 1.6 to 9.8, b* value was said to be 10.4 to 29.0. The A2 zirconia used in this study (L* =71.38, a* = –1.28, b* =9.20) showed L* values within the range of natural teeth, but a* and b* values were lower than natural teeth.

In this in vitro study, when the white opaque coloring liquid was applied, the L* (81.55) value increased to make the color brighter, and the a* (–1.10) value decreased to show a greenish tendency. Even when compared to natural teeth (L* =64.3–78, a* =2.6–2.8, b* =9.9–25.7), it can be seen that the L* value is high and the a* value is low (32). When A2 coloring liquid was applied, the L* value (67.61 to 69.05) decreased and the color became dark, the a* value (–0.18 to 0.78) increased to show a reddish tendency, and the b* value (10.34 to 10.93) increased to show yellowish tendency. In this in vitro study, the L* value of the WC group applied with both A2 coloring liquid and White opaque coloring liquid was significantly lowered and darker than that of the W group applied with White opaque coloring liquid and the a* value increased significantly and the red tendency was strengthened. Therefore, it is judged that if two types of coloring liquids are used together, the color of zirconia can be complemented and adjusted similarly to the color of natural teeth. The color differences between the Z and ZT in the N group without color treatment was 4.38, and the color differences between the Z and ZT in the W group applied with White opaque coloring liquid was 1.59, the color differences greatly decreased. The color (L* =76.63, a* = –0.08, b* =13.72) of the WC6 group, which was applied once with White opaque coloring liquid after 6 application of A2 coloring liquid, was most similar to natural teeth.

In this in vitro study, the effect of coloring treatment of translucent zirconia on the masking of color of titanium abutment was evaluated using A2 colorant, white opaque colorant, and cement. In conclusion, the effect of masking of color is closely related to translucency. There are many different types, colors, and translucency of zirconia currently on the market. However, zirconia is used without clear information on translucency in clinical, and when zirconia with high translucency is used for titanium abutment, the color of the titanium abutment is exposed. As a result of this study, depending on the translucency of zirconia, the effect of masking of color on various types of substructures varies and may ultimately affect the final color. Therefore, it is necessary to have a standard for translucency of zirconia that can properly mask color according to the type of substructure of zirconia restoration. A2, one of the most commonly used colors in clinical practice, was chosen as the colorant.

In case of using titanium abutment, it is judged that it is necessary to use a full ceramic restoration with low translucency or to lower translucency by using coloring treatment such as white opaque coloring liquid. And it is necessary to develop an opaque coloring liquid with a color for the efficiency of work in clinical.

This study had limitations because it used one type of coloring liquid, white opaque coloring liquid, and cement for one type and thickness of zirconia. In the future, it is considered necessary to study the appropriate translucency that is effective for masking of color with titanium or zirconia abutment using zirconia with various translucency and various types of coloring liquid.

Conclusions

Within the limitations of this in vitro study, the following conclusions were obtained:

- 1. The application of the white opaque coloring liquid to the translucent zirconia was effective on the masking of color of the titanium abutment.

- 2. When A2 and white opaque coloring liquid were applied together to translucent zirconia, the effect of masking of color of the titanium abutment increased and a color could approch natural teeth.

- 3. The adhesion of the resin cement to the translucent zirconia did not affect the masking of color of the titanium abutment.

- 4. As the translucency of zirconia increases, the effect of masking of color of the titanium abutment decreases.

Acknowledgments

The authors thank ARUM Dentisty for their contributions in metal plate manufacture in this article

References

-

Vichi A, Louca C, Corciolani G, Ferrari M. Color related to ceramic and zirconia restorations: A review. Dent Mater. 2011;27(1):97-108.

[https://doi.org/10.1016/j.dental.2010.10.018]

-

Douglas RD, Steinhauer TJ, Wee AG. Intraoral determination of the tolerance of dentists for perceptibility and acceptability of shade mismatch. J Prosthet Dent. 2007;97(4):200-8.

[https://doi.org/10.1016/j.prosdent.2007.02.012]

-

Ishikawa-Nagai S, Yoshida A, Sakai M, Kristiansen J, Da Silva JD. Clinical evaluation of perceptibility of color differences between natural teeth and all-ceramic crowns. J Dent. 2009;37(Suppl. 1):e57-63.

[https://doi.org/10.1016/j.jdent.2009.04.004]

-

Sen N, Isler S. Microstructural, physical, and optical characterization of high-translucency zirconia ceramics. J Prosthet Dent. 2020;123(5):761-8.

[https://doi.org/10.1016/j.prosdent.2019.05.004]

-

Wang F, Takahashi H, Iwasaki N. Translucency of dental ceramics with different thicknesses. J Prosthet Dent. 2013;110(1):14-20.

[https://doi.org/10.1016/S0022-3913(13)60333-9]

-

Tuncel I, Eroglu E, Sari T, Usumez A. The effect of coloring liquids on the translucency of zirconia framework. J Adv Prosthodont. 2013;5(4):448-51.

[https://doi.org/10.4047/jap.2013.5.4.448]

-

Vichi A, Ferrari M, Davidson CL. Influence of ceramic and cement thickness on the masking of various types of opaque posts. J Prosthet Dent. 2000;83(4):412-7.

[https://doi.org/10.1016/S0022-3913(00)70035-7]

-

Tabatabaian F, Taghizade F, Namdari M. Effect of coping thickness and background type on the masking ability of a zirconia ceramic. J Prosthet Dent. 2018;119(1):159-65.

[https://doi.org/10.1016/j.prosdent.2017.03.009]

-

Bacchi A, Boccardi S, Alessandretti R, Pereira GKR. Substrate masking ability of bilayer and monolithic ceramics used for complete crowns and the effect of association with an opaque resin-based luting agent. J Prosthodont Res. 2019;63(3):321-6.

[https://doi.org/10.1016/j.jpor.2019.01.005]

-

Chongkavinit P, Anunmana C. Optical effect of resin cement, abutment material, and ceramic thickness on the final shade of CAD-CAM ceramic restorations. J Prosthet Dent. 2021;125(3):517.e1-e8.

[https://doi.org/10.1016/j.prosdent.2020.09.029]

-

Bressan E, Paniz G, Lops D, Corazza B, Romeo E, Favero G. Influence of abutment material on the gingival color of implant-supported all-ceramic restorations: a prospective multicenter study. Clin Oral Implants Res. 2011;22(6):631-7.

[https://doi.org/10.1111/j.1600-0501.2010.02008.x]

-

Jirajariyavej B, Wanapirom P, Anunmana C. Influence of implant abutment material and ceramic thickness on optical properties. J Prosthet Dent. 2018;119(5):819-25.

[https://doi.org/10.1016/j.prosdent.2017.05.015]

-

Foong JKW, Judge RB, Palamara JE, Swain MV. Fracture resistance of titanium and zirconia abutments: An in vitro study. J Prosthet Dent. 2013;109(5):304-12.

[https://doi.org/10.1016/S0022-3913(13)60306-6]

-

Dede DÖ, Armağanci A, Ceylan G, Celik E, Cankaya S, Yilmaz B. Influence of implant abutment material on the color of different ceramic crown systems. J Prosthet Dent. 2016;116(5):764-9.

[https://doi.org/10.1016/j.prosdent.2016.04.004]

-

Bayındır BC, Nemli SK, Bayarı SH, Bal BT. The effect of monolithic zirconia thickness on the degree of conversion of dental resin cements: ATR-FTIR spectroscopic analysis. Vibrational Spectroscopy. 2016;86:212-7.

[https://doi.org/10.1016/j.vibspec.2016.07.015]

-

Woo ES, Goldstein G, Choi M, Bromage TG. In vitro shear bond strength of 2 resin cements to zirconia and lithium disilicate: An in vitro study. J Prosthet Dent. 2021;125(3):529-34.

[https://doi.org/10.1016/j.prosdent.2020.02.020]

-

Lee TH, Ahn JS, Shim JS, Han CH, Kim SJ. Influence of cement thickness on resin-zirconia microtensile bond strength. J Adv Prosthodont. 2011;3(3):119-25.

[https://doi.org/10.4047/jap.2011.3.3.119]

-

Kale E, Seker E, Yilmaz B, Özcelik TB. Effect of cement space on the marginal fit of CAD-CAM-fabricated monolithic zirconia crowns. J Prosthet Dent. 2016;116(6):890-5.

[https://doi.org/10.1016/j.prosdent.2016.05.006]

-

Chen JY, Pan YH. Zirconia implant abutments supporting single all-ceramic crowns in anterior and premolar regions: A six-year retrospective study. Biomed J. 2019;42(5):358-64.

[https://doi.org/10.1016/j.bj.2019.05.001]

-

Almeida JR, Schmitt GU, Kaizer MR, Boscato N, Moraes RR. Resin-based luting agents and color stability of bonded ceramic veneers. J Prosthet Dent. 2015;114(2):272-277.

[https://doi.org/10.1016/j.prosdent.2015.01.008]

-

Chang J, Da Silva JD, Sakai M, Kristiansen J, Ishikawa-Nagai S. The optical effect of composite luting cement on all ceramic crowns. J Dent. 2009;37(12):937-43.

[https://doi.org/10.1016/j.jdent.2009.07.009]

-

Malkondu O, Tinastepe N, Kazazoglu E. Influence of type of cement on the color and translucency of monolithic zirconia. J Prosthet Dent. 2016;116(6):902-8.

[https://doi.org/10.1016/j.prosdent.2016.05.001]

-

Bayindir F, Koseoglu M. The effect of restoration thickness and resin cement shade on the color and translucency of a high-translucent monolithic zirconia. J Prosthet Dent. 2018;123(1):149-54.

[https://doi.org/10.1016/j.prosdent.2018.11.002]

-

Alp G, Subaşı MG, Seghi RR, Johnston WM, Yilmaz B. Effect of shading technique and thickness on color stability and translucency of new generation translucent zirconia. J Dent. 2018;73:19-23.

[https://doi.org/10.1016/j.jdent.2018.03.011]

-

Sen N, Sermet IB, Cinar S. Effect of coloring and sintering on the translucency and biaxial strength of monolithic zirconia. J Prosthet Dent. 2018;119(2):308. e1-e7.

[https://doi.org/10.1016/j.prosdent.2017.08.013]

-

Nam JY, Park MG. Effects of treatment with aqueous and acid-based coloring liquid on the color of zirconia. J Prosthet Dent. 2019;121(2):363.e1-e5.

[https://doi.org/10.1016/j.prosdent.2018.09.015]

-

Kim HK, Kim SH. Effect of the number of coloring liquid applications on the optical properties of monolithic zirconia. Dent Mater. 2014;30(9):e220-37.

[https://doi.org/10.1016/j.dental.2014.04.008]

-

Kim HK, Kim SH. Optical properties of pre-colored dental monolithic zirconia ceramics. J Dent. 2016;55:75-81.

[https://doi.org/10.1016/j.jdent.2016.10.001]

-

Tuncel I, Özat P, Eroglu E. Effects of coloring procedures on zirconia/veneer ceramics bond strength. J Adv Prosthodont. 2014;6(6):451-5.

[https://doi.org/10.4047/jap.2014.6.6.451]

- Johnston WM, Ma T, Kienle BH. Translucency parameter of colorants for maxillofacial prostheses. Int J Prosthodont. 1995;8(1):79-86.

-

Dai S, Chen C, Tang M, Chen Y, Yang L, He F, Chen B, Xie H. Choice of resin cement shades for a high-translucency zirconia product to mask dark, discolored or metal substrates. J Adv Prosthodont. 2019;11(5):286-96.

[https://doi.org/10.4047/jap.2019.11.5.286]

-

O’Brien WJ, Groh CL, Boenke KM. A one-dimensional color order system for dental shade guides. Dent Mater. 1989;5(6):371-4.

[https://doi.org/10.1016/0109-5641(89)90102-4]

-

Cho B-H, Lim Y-K, Lee Y-K. Comparison of the color ofnatural teeth measured by a colorimeter and shade visionsystem. Dent Mater. 2007;23(10):1307-12.

[https://doi.org/10.1016/j.dental.2006.11.008]