Effect of speed sintering on flexural strength, density, and linear shrinkage of monolithic zirconia

Abstract

The purpose of this in vitro study was to evaluate the effect of speed sintering on flexural strength, density, and linear shrinkage of monolithic zirconia. Four hundred Ø18.7×1.7-mm presintered zirconia specimens were divided into 8 groups (n=50) based on the sintering times (speed (60, 90, and 120 min) or normal (540 min)) and temperatures (1400, 1450, 1500, and 1550 ℃). The mechanical properties (Vickers hardness, biaxial flexural strength, and fracture toughness) and physical properties (linear shrinkage, density, and porosity) were examined. The crystallite size of zirconia was calculated using scherer’s formula. The mechanical properties (biaxial flexural strength, Vickers hardness, and fracture toughness) of all specimens increased with increasing sintering times and temperatures. The biaxial flexural strength of the SS groups sintered 1500 ℃ and 1550 ℃ with 120 min showed similar value compared with NS groups. The SS 120 and NS groups showed similar the linear shrinkage percentages at all temperatures. The porosity decreased with increasing sintering times and temperatures in all specimens. The sintered and relative density and the average crystallite size increased with increasing sintering times and temperatures in all specimens. The average crystallite size ranged from 70.1 nm to 129.8 nm. XRD analysis showed the presence of a tetragonal metastable phase in all groups before and after sintering. The biaxial flexural strength values under speed sintering (1500 ℃ and 1550 ℃, 120 min) were similar to those of normal sintering groups.

초록

본 연구의 목적은 단일관 지르코니아의 굽힘강도, 밀도 및 선수축에 대한 급속소결의 효과를 평가하는 것이다. 소결 시간(급속소결(60, 90, 120분) 또는 일반소결(540분))과 온도(1400, 1450, 1500, 1550 ℃)에 따라 Ø18.7×1.7 mm 반소결 지르코니아 시편 400개를 8개 그룹(n=50)으로 나누어 기계적 특성(비커스 경도, 이축 굽힘강도 및 파괴인성)과 물리적 특성(선수축, 밀도 및 다공성)을 측정하였다. 지르코니아의 결정 크기는 scherer’s 공식을 사용하여 계산하였다. 모든 시편의 기계적 특성(이축 굽힘강도, 비커스 경도 및 파괴인성)은 소결 시간과 온도가 증가함에 따라 증가하였다. 1500 ℃와 1550 ℃에서 120분간 소결한 SS 그룹의 이축 굽힘강도는 NS 그룹과 유사하였다. SS 120과 NS 그룹은 모든 온도에서 유사한 선수축률을 보였다. 모든 시편에서 소결 시간과 온도가 증가함에 따라 다공성이 감소하였다. 소결 및 상대 밀도, 평균 결정 크기는 모든 시편에서 소결 시간과 온도가 증가함에 따라 증가하였다. 평균 결정 크기는 70.1 nm에서 129.8 nm 범위였다. XRD 분석 결과 소결 전후의 모든 그룹에서 정방정 준안정상이 관찰되었다. 급속소결(1500 ℃ 및 1550 ℃, 120분)에서의 이축 굽힘강도 값은 일반 소결 그룹과 유사하였다.

Keywords:

monolithic zirconia, speed sintering, flexural strength, linear shrinkage키워드:

단일관 지르코니아, 급속 소결, 굽힘강도, 선수축Introduction

Presintered or sintered yttria-stabilized tetragonal zirconia polycrystal (Y-TZP) block, or disc, is used for prosthesis using the dental computer-aided design and computer-aided manufacturing (CAD/CAM) system (1-3). In order to compensate for sintered shrinkage that occurs during sintering in the zirconia prosthesis manufacturing process, it is manufactured about from 10% to 25% larger than the original size (4, 5). Sintering process increases the mechanical strength of zirconia while allowing the complete crystallization by traversing the Y-TZP particle boundary without liquid involvement (6).

Zirconia sintering requires temperatures above 1400 ℃ generally. When a particle is sintered and cooled at a high temperature (over 1400 ℃), a change in phase occurs from a tetragonal to a cubic structure at approximately 1200 ℃ (7). Upon heating, the monoclinic phase of zirconia starts transforming to the tetragonal phase at 1187 ℃, peaks at 1197 ℃, and finishes at 1206 ℃. On cooling, the transformation from the tetragonal to the monoclinic phase starts at 1052 ℃, peaks at 1048 ℃, and finishes at 1020 ℃, exhibiting a hysteresis behavior. The zirconia tetragonal-to-monoclinic phase transformation is known to be a martensitic transformation (8, 9). During this zirconia phase transformation, the unit cell of monoclinic configuration occupies about 4% more volume than the tetragonal configuration, which is a relatively large volume change. This could result in the formation of ceramic cracks if no stabilizing oxides were used (7-9).

The zirconia sintering method is classified into two types. First, there is a method of sintering the heating element by using super kanthal Heater, and secondly, there is sintering method by using other devices (plasma, microwave) (10, 11). The sintering of zirconia for dental applications need process time, which involves a “slow” heating and cooling rate coupled with a prolonged dwell time. The common sintering method is heated from the surface of the material and transferred heat to the inside.

Recently, to reduce produce time of the zirconia prosthesis, speed sintering schedules within 60 to 240 min used as speed sintering instead of conventional sintering within 7 to 10 hours. The zirconia can be densified after a dwell time of 25 min at around 1510 ℃ by speed sintering (12). Several commercially super-speed sintering furnaces are already in the market, such as in Fire HTC speed (Sirona) (12, 13).

According to the other research, speed sintering produces equal or greater mechanical properties (fracture toughness and flexural strength) than conventional sintering process (14-16). There have been some evaluations on the flexural strength of zirconia (17-19). Sintering conditions such as sintering temperature and time affect the grain size, transparency, flexural strength, and fracture resistance of zirconia particles (20-22). Density and porosity affect the mechanical properties of zirconia (23-25). In speed sintering, grain growth is limited due to the shorter sintering time (23, 26, 27), however, before heat is transferred to the interior, it is sintered from the exterior, leaving porosity (25). There are studies on the effect of sintering conditions on the phase transformation of zirconia (25).

Although, speed and super-speed sintered dental zirconia are already applied in dental fields, studies on the stability of the zirconia prosthesis during speed sintering are still insufficient, and studies on appropriate sintering temperatures and conditions are also necessary. Therefore, the purpose of this study is to compare and analyze the mechanical properties as changing of sintering temperature and time with presintered monolithic zirconia block and super kanthal heater sintering furnace. The null hypothesis was that the sintering times and temperatures would not affect the mechanical properties of zirconia ceramics.

Materials and Methods

A presintered monolithic zirconia block (RAZOR 1100, UNC International, Seoul, Korea) consisting of ZrO2 (85 to 96 vol%), Y2O3 (4 to 6 vol%), Al2O3 (0 to 1 vol%), and HfO2 (4 to 5 vol%) was used as the raw material. Ø18.7×1.7-mm a total of 400 specimens were cut from the block by using a CAD-CAM milling machine (InLab MC X5, Dentsply Sirona, Charlotte, NC, USA). The milled specimens were ground to a thickness of 2 mm by using abrasive papers (P1200, P1500, and P2500, Imperial wet or dry, 3M, Maplewood, MN, USA). The specimens were divided into 8 groups (n=50) based on the sintering conditions speed (60, 90, 120 min) or normal (540 min) (SS 60, SS 90, SS 120, and NS 540) and sintering temperatures (1400 ℃, 1450 ℃, 1500 ℃, and 1550 ℃). Each specimen was sintered in a sintering furnace (Zircom-plus, KDF, Denken Highdental, Kyoto, Japan). The sintering furnace was heated to a final temperature (1400, 1450, 1500, 1550 ℃) with different heating rate. The speed sintering schedule was heating at 50 ℃/min to 1100 ℃ and then at 50 ℃/min to final temperature, with a dwell time of 11, 41, 71 min, and cooled to room temperature. The total sintering time was 60, 90, 120 min. The normal sintering schedule was heating at 9.1 ℃/min to 1100 ℃, with a dwell time of 80 min and then at 2.8 ℃/min to final temperature, with a dwell time of 60 min, and cooled to room temperature. The total sintering time was 540 min.

The biaxial flexural strength test was performed according to the International Organization for Standardization (ISO) 6872:2015 (28), with 15 specimens per group after polishing and drying. The zirconia specimens were loaded at a crosshead speed of 1.0 mm/min until fracture occurred. Sintered specimen was polished to a surface of 1 µm and tested using a Vickers hardness tester (V-Test I, Bareiss Prüfgerätebau GmbH, Oberdischingen, Germany). Vicker's hardness was measured by indentation with a load of 1 ㎏f (9.8 N) for 15 seconds. Fracture toughness of the specimen was measured using the Indentation Fracture method. Weibull analysis was performed to show the reliability of this experiment (29, 30).

The specimen surfaces were polished flat by using a 1 µm diamond suspension finish, and then thermally etched at 1150 ℃ for 30 min. The densities were estimated by using the Archimedes principle. The relative density (%)=(measured density/theoretical density)×100. The porosity was calculated using the relative density obtained by dividing the sintering density by the theoretical density as the following formula: P (%)=(1–Db/Dth)×100, where P is porosity; Db, sintered density; Dth, theoretical density.

To analyze the linear shrinkage, the dimensions of the sintered specimens were measured before and after sintering with Vernier calipers (Series 500, Mitutoyo, Kawasaki, Japan). The crystal phases of the sintered green bodies were analyzed with X-ray diffraction (XRD, MiniFlex, Rigaku, Tokyo, Japan). The crystallite size of zirconia was calculated by using scherer’s formula given in following formula: D=0.9λ/BCosθ, Where D is crystallite size; λ, wavelength of X-rays used (1.5406 Å); B, full width at half maximum and θ is diffraction angle.

A statistical software program (IBM SPSS Statistics, v26.0; IBM Corp, Chicago, IL, USA) was used for statistical analysis of the data. The data were analyzed with one-way and two-way analyses of variance with Scheffé test (α =.05).

Results

Table 1 summarizes the two-way ANOVA of the mechanical properties (biaxial flexural strength, vickers hardness, and fracture toughness) of the specimens. The two-way ANOVA showed statistically significant differences among the tested groups for biaxial flexural strength, Vickers hardness, and fracture toughness (P<.001).

The mean value for the mechanical properties (biaxial flexural strength, Vickers hardness, and fracture toughness) in each group is presented in Table 2. The mechanical properties of all specimens increased with increasing sintering times and temperatures (P<.001). When the sintering times increased from 60 min to 540 min and the sintering temperature increased from 1400 ℃ to 1550 ℃, the biaxial flexural strength value increased significantly (P<.001). The biaxial flexural strengths of the SS 60, 90, 120 groups were significantly lower than those in the other NS group (P<.001). When the sintering times increased from 60 min to 540 min and the sintering temperature increased from 1400 ℃ to 1550 ℃, the Vickers hardness and the fracture toughness value increased significantly (P<.001). The Vickers hardness and the fracture toughness value of the SS 60, 90, 120 groups were significantly lower than those in the other NS group (P<.001).

Mean and standard deviations of biaxial flexural strength, Vickers hardness, fracture toughness with different sintering temperatures and times

One-way ANOVA identified a statistically significant difference in mechanical properties (biaxial flexural strength, Vickers hardness, and fracture toughness) among the 16 groups (Biaxial flexural strength, F=94.214; Hardness, F=28.592; Fracture toughness, F=118.418, P<.001) (Table 3). The biaxial flexural strength of the SS groups sintered 1500 ℃ and 1550 ℃ with 120 min showed similar value compared with NS groups (P<.001).

Mean and standard deviations of biaxial flexural strength, Vickers hardness, fracture toughness with different sintering temperatures and times by one-way ANOVA

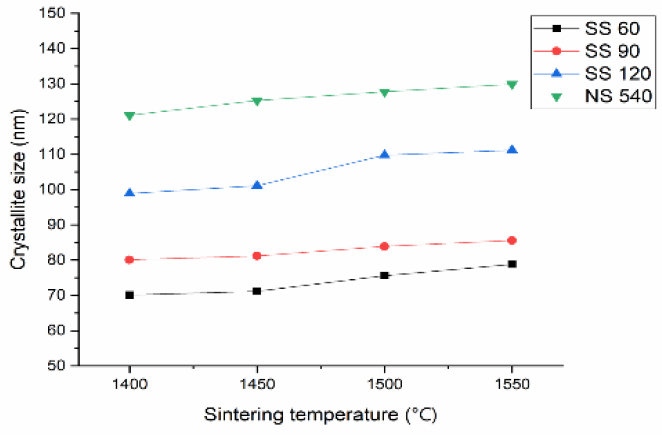

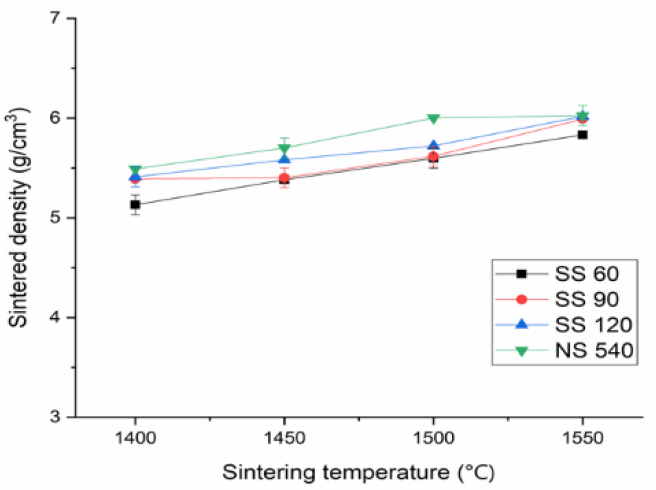

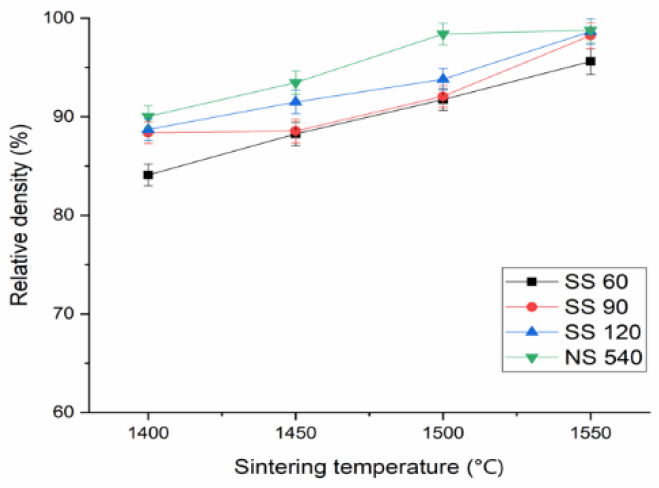

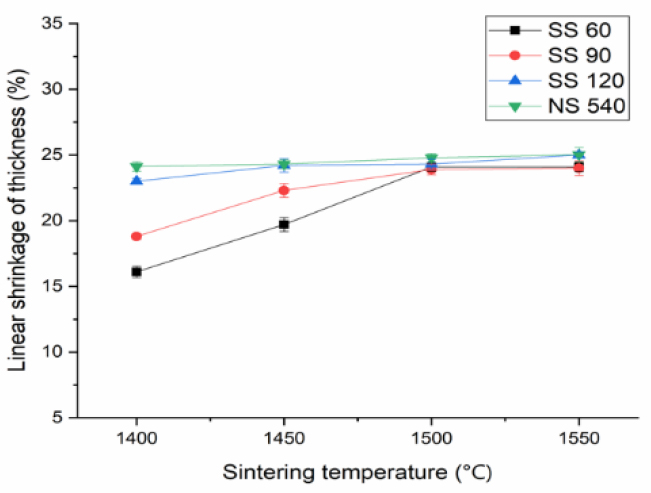

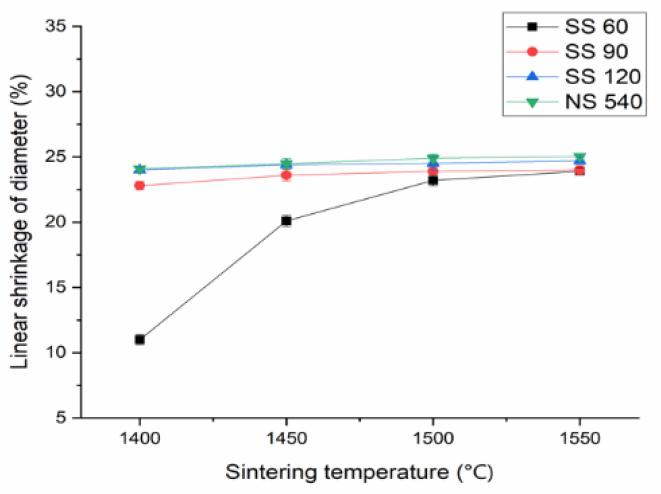

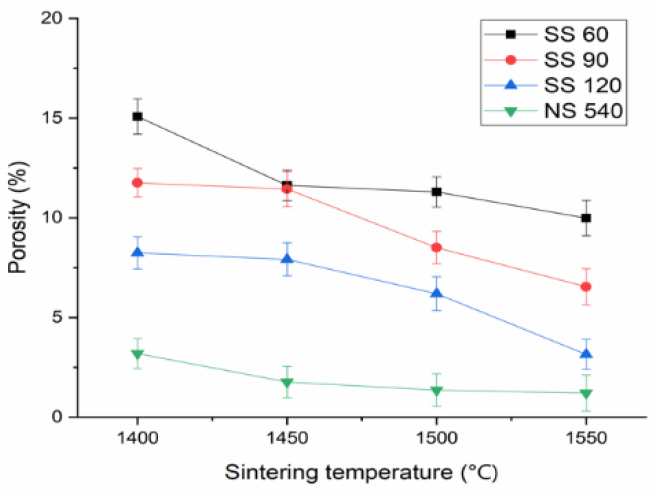

The sintered and relative density of the specimens under speed sintering groups increased with increasing sintering temperature and time in Figure 1 and 2 . In normal sintering groups, the sintered and relative density of the specimens increased until 1500 ℃ with increasing sintering temperature and time. After 1500 ℃, the sintered and relative density of the specimens are shown in similar value. The linear shrinkage percentages in thickness and diameter under speed sintering groups increased with increasing sintering time in Figure 3 and 4.

Sintered density with different sintering temperatures (1400, 1450, 1500, 1550 ℃) and times (60, 90, 120, 540 min).

Relative density with different sintering temperatures (1400, 1450, 1500, 1550 ℃) and times (60, 90, 120, 540 min).

Linear shrinkage in thickness of sintered specimens at different sintering temperatures (1400, 1450, 1500, 1550 ℃) and times (60, 90, 120, 540 min).

Linear shrinkage in diameter of sintered specimens at different sintering temperatures (1400, 1450, 1500, 1550 ℃) and times (60, 90, 120, 540 min).

The SS 60 group showed an increase in the linear shrinkage percentages in thickness and diameter as the temperature increased, but the SS 90, SS 120 and NS groups showed no change in linear shrinkage even with the increase in temperature. SS 120 and NS groups showed similar the linear shrinkage percentages. The porosity decreased with increasing sintering times and temperatures in all specimens in Figure 5. In normal sintering groups, the porosity of the zirconia specimens decreased until 1500 ℃ with increasing sintering times and temperatures. After 1500 ℃, the porosity of the zirconia specimens is shown in similar value.

Porosity of sintered specimens at different sintering temperatures (1400, 1450, 1500, 1550 ℃) and times (60, 90, 120, 540 min).

Crystallite size of NS groups ranged from 121.1 to 129.8 nm with the predominance of large crystallite size and decreased porosity than the other groups in Figure 6. While specimens of SS groups showed slightly smaller crystallite size than those of NS groups that varied from 70.1 to 112.2 nm.

Discussion

This study evaluated the influence of speed sintering under different sintering times (60, 90, 120, and 540 min) and sintering temperatures (1400, 1450, 1500, and 1550 ℃) on the mechanical properties. According to the results of this study, the null hypothesis that the sintering times and temperatures would have no influence on the mechanical properties of zirconia ceramics, were rejected except the SS groups sintered 1500 ℃ and 1550 ℃ with 120 min.

The mechanical properties of all specimens increased with increasing sintering temperatures and times in this study. When the sintering times increased from 60 min to 540 min and the sintering temperature increased from 1400 ℃ to 1550 ℃, the mechanical properties (biaxial flexural strength, Vickers hardness, and fracture toughness) increased significantly by two-way ANOVA analysis. However, the biaxial flexural strength of the SS groups sintered 1500 ℃ and 1550 ℃ with 120 min showed similar value compared to NS groups by one-way ANOVA analysis.

The mechanical properties of commercial dental zirconia (3Y-TZP) are a crucial factor for determining clinical indications regarding flexural strength testing by ISO 6872:2015 (28-30). Among the several flexural strengths, biaxial flexural strength is an important mechanical property that aids in predicting the performance of ceramic material. It can be defined as the final force required to cause fracture (31). The mean biaxial flexural strength values of speed sintering groups were found to be from 604.65±68.68 to 948.83±49.45 MPa, respectively. On the other hand, that values of normal sintering groups were found to be from 872.93 ±53.75 to 928.43±53.81 MPa. There have been different reports on the biaxial flexural strength of Cercon, which it was reported to be from 911±95 to 1141±121 MPa (17, 18). In other study, that of Lava was reported as 1100 MPa (19). For SS 60, 90 group, the biaxial flexural strength values were significantly lower than that in NS 540 group. Only the biaxial flexural strength values of specimen under 120 min sintering time at 1500 ℃ (897.64 ±58.77 MPa) and 1550 ℃ (948.83±49.45 MPa) was resulted in similar value of that compared with specimens of NS 540 group (Table 3).

The conventional sintering times for zirconia need time from 4 to 12 hours when compared with other materials, which restricts the use of zirconia for applications. In contrast, speed sintering is intended to shorten the sintering process, which normally takes several hours. The sintering of zirconia affects to the grain size and physical properties. That is a very important factor to influence final microstructure and material stability including mechanical properties (20, 21). Asaad et el (22) explained that when comparing high-speed sintering and conventional sintering of zirconia crowns with the same thicknesses, high speed sintering of monolithic zirconia crowns showed the highest fracture load. In a different study where the samples were fast sintered by putting them in a pre-heated furnace at 1580 ℃ for 10 min, the flexural strength of zirconia ceramics was significantly improved (14). Cokic et el (16) reported that speed and conventionally sintered zirconia revealed similar density, microstructure, average strength and hydrothermal aging stability. The variations in sintering process of zirconia can directly affect microstructure and properties of zirconia, this may be related to crystal structure maturation, elimination of defects on grain boundaries, and grain size expansion.

The flexural strength of the zirconia decreases with the increase of grain size. The increase of sintering temperature and time was resulted in an increase in the crystallite size (13, 20, 21). By increasing the temperature above 1100 ℃, surface diffusion can be activated and it can cause sintering and formation of necks between particles. It can be considered that the crystallite growth by means of an interfacial reaction (32). The speed sintering led to a reduction in the crystallite size in Figure 6. The speed sintering restrains the surface diffusion for the coarsening mechanisms, resulting in the reduced grain size (23). The grain growth is diminished due to shorter processing time for speed sintering (23, 26, 27). In this study, the growth of crystalline particles did not result in a decrease in flexural strength.

The density values of specimens of are dependent on porosity value and growth of crystalline particles. The difference values of sintered density approaching theoretical density is due to the existence of porosity. The porosity of the specimens is influenced by the factor of grain growth. It can be clearly seen that the relative density increases gradually with the increase in sintering time, temperature in Figure 2. The speed sintering leads to the formation of large thermal gradients, which can cause the exterior regions of the specimens to sinter before the interior, resulting in residual porosity (25). As the sintering temperature was increased, the porosity was decreased significantly in Figure 5. Only specimens under sintered 1550 ℃ with 120 min showed lower porosity value than 5%. The zirconia specimens with higher density and lower porosity are resulted in higher mechanical properties (24).

The theoretical density of the TZP material was 6.10 g/cm3, and it is appropriate for the density of zirconia to exceed 6.00 g/cm3 in ISO 13356 (33). The sintered density of all specimens ranged from 5.13 to 6.026 g/cm3. In normal sintering groups, at 1500 ℃ or higher, the density value of zirconia approaches 6.00 g/cm3. In speed sintering groups, only the SS 90 and SS 120 groups sintered at 1550 ℃ have a density value close to 6.00 g/cm3.

The limitations of the study included the lack of comparison with other materials. The one zirconia block was used for this study. Further studies on the effect of speed sintering on color and transparency of zirconia are needed. It is also necessary to study the speed sintering furnace developed in the market.

Conclusions

Based on the findings of this in vitro study, the following conclusions were drawn. Increasing the sintering temperature and time leaded to enhanced mechanical properties of dental zirconia. The specimens under speed sintering condition (1500 ℃ and 1550 ℃, 120 min) showed similar value of biaxial flexural strength in normal sintering specimens. The specimens under speed sintering (1550 ℃, 90 and 120 min) and normal sintering condition have a density value close to 6.00 g/cm3. Speed sintering with 120 minutes at 1500 ℃ and 1550 ℃ may be suitable method for clinical application without purchasing any facilities (high speed sintering furnace).

References

-

Krogstad JA, Gao Y, Bai J, Wang J, Lipkin DM, Levi CG. In situ diffraction study of the high-temperature decomposition of t-Zirconia. J Am Ceram Soc. 2015;98(1):247-54.

[https://doi.org/10.1111/jace.13249]

-

Lipkin DM, Krogstad JA, Gao Y, Johnson CA, Nelson WA, Levi CG. Phase Evolution upon Aging of Air-Plasma Sprayed t-zirconia coatings: I-synchrotron X-ray diffraction. J Am. 2013;96(1):290-8.

[https://doi.org/10.1111/j.1551-2916.2012.05451.x]

-

Lazar DR, Bottino MC, Özcan M, Valandro LF, Amaral R, Ussui V, Bressiani AH. Y-TZP ceramic processing from coprecipitated powders: A comparative study with three commercial dental ceramics. Dent Mater. 2008;24(12):1676-85.

[https://doi.org/10.1016/j.dental.2008.04.002]

-

Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent Mater. 2008;24(3):299-307.

[https://doi.org/10.1016/j.dental.2007.05.007]

-

Guazzato M, Albakry M, Ringer SP, Swain MV. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dent Mater. 2004;20(5):449-56.

[https://doi.org/10.1016/j.dental.2003.05.002]

-

Wang H, Aboushelib MN, Feilzer AJ. Strength influencing variables on CAD/CAM zirconia frameworks. Dent Mater. 2008;24(5):633-8.

[https://doi.org/10.1016/j.dental.2007.06.030]

-

Luthardt RG, Holzhüter M, Sandkuhl O, Herold V, Schnapp JD, Kuhlisch E, Walter M. Reliability and properties of ground Y-TZP-zirconia ceramics. J Dent Res. 2002;81(7):487-91.

[https://doi.org/10.1177/154405910208100711]

-

Jue JF, Virkar AV. Fabrication, microstructural characterization, and mechanical properties of polycrystalline t’-zirconia. J Am Ceram Soc. 1990;73(12):3650-7.

[https://doi.org/10.1111/j.1151-2916.1990.tb04271.x]

-

Zhang F, Inokoshi M, Batuk M, Hadermann J, Naert I, Van Meerbeek B, Vleugels J. Strength, toughness and aging stability of highly-translucent Y-TZP ceramics for dental restorations. Dent Mater. 2016;32(12):327-37.

[https://doi.org/10.1016/j.dental.2016.09.025]

-

Samodurova A, Kocjan A, Swain MV, Kosmač T. The combined effect of alumina and silica co-doping on the ageing resistance of 3Y-TZP bioceramics. Acta Biomater. 2015;11:477-87.

[https://doi.org/10.1016/j.actbio.2014.09.009]

-

Hallmann L, Ulmer P, Reusser E, Louvel M, Hämmerle CHF. Effect of dopants and sintering temperature on microstructure and low temperature degradation of dental Y-TZP-zirconia. J Eur Ceram Soc. 2012;32(16):4091-104.

[https://doi.org/10.1016/j.jeurceramsoc.2012.07.032]

-

MR Kaizer, PC Gierthmuehlen, MBF dos Santos, SS Cava, Y Zhang. Speed sintering translucent zirconia for chairside one-visit dental restorations: Optical, mechanical, and wear characteristics. Ceram Int. 2017;43(14):10999-11005.

[https://doi.org/10.1016/j.ceramint.2017.05.141]

-

Ebeid K, Wille S, Hamdy A, Salah T, El-Etreby A, Kern M. Effect of changes in sintering parameters on monolithic translucent zirconia. Dent Mater. 2014;30(12):419-24.

[https://doi.org/10.1016/j.dental.2014.09.003]

-

Ersoy NM, Aydogdu HM, Degirmenci BU, Cokuk N, Sevimay M. The effects of sintering temperature and duration on the flexural strength and grain size of zirconia. Acta Biomater Odontol Scand. 2015;1(2-4):43-50.

[https://doi.org/10.3109/23337931.2015.1068126]

-

Jansen JU, Lümkemann N, Letz I, Pfefferle R, Sener B, Stawarczyk B. Impact of high-speed sintering on translucency, phase content, grain sizes, and flexural strength of 3Y-TZP and 4Y-TZP zirconia materials. J Prosthet Dent. 2019;122(4):396-403.

[https://doi.org/10.1016/j.prosdent.2019.02.005]

-

Cokic SM, Vleugels J, Van Meerbeek B, Camargo B, Willems E, Li M, Zhang F. Mechanical properties, aging stability and translucency of speed-sintered zirconia for chairside restorations. Dent Mater. 2020;36(7):959-72.

[https://doi.org/10.1016/j.dental.2020.04.026]

-

Yilmaz H, Aydin C, Gul BE. Flexural strength and fracture toughness of dental core ceramics. J Prosthet Dent. 2007;98(2):120-8.

[https://doi.org/10.1016/S0022-3913(07)60045-6]

-

Chen YM, Smales RJ, Yip KHK, Sung WJ. Translucency and biaxial flexural strength of four ceramic core materials. Dent Mater. 2008;24(11):1506-11.

[https://doi.org/10.1016/j.dental.2008.03.010]

-

Pittayachawan P, McDonald A, Petrie A, Knowles JC. The biaxial flexural strength and fatigue property of Lava Y-TZP dental ceramic. Dent Mater. 2007;23(8):1018-29.

[https://doi.org/10.1016/j.dental.2006.09.003]

-

Stawarczyk B, Özcan M, Hallmann L, Ender A, Mehl A, Hammerlet CH. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Investig. 2013;17(1):269-74.

[https://doi.org/10.1007/s00784-012-0692-6]

-

Stawarczyk B, Emslander A, Roos M, Sener B, Noack F, Keul C. Zirconia ceramics, their contrast ratio and grain size depending on sintering parameters. Dent Mater J. 2014;33(5):591-298.

[https://doi.org/10.4012/dmj.2014-056]

-

Asaad R, Aboushahba Mostafa. Influence of different sintering protocols on translucency and fracture resistance of monolithic zirconia crowns. Materials Science. 2020;66(4) 42653:1258.

[https://doi.org/10.21608/edj.2020.42653.1257]

-

Zhang HH, Xu YL, Wang B, Zhang X, Yang JF, Niihara K, Effects of heating rate on the microstructure and mechanical properties of rapid vacuum sintered translucent alumina. Ceram Int. 2015;41(9):12499.

[https://doi.org/10.1016/j.ceramint.2015.05.136]

-

Buj-Corral I, Vidal D, Tejo-Otero A, Padilla JA, Xuriguera E, Fenollosa-Artés F. Characterization of 3D Printed Yttria-Stabilized Zirconia Parts for Use in Prostheses. Nanomaterials (Basel). 2021;11(11):2942.

[https://doi.org/10.3390/nano11112942]

-

Nonaka K, Teramae M, Pezzotti G. Evaluation of the Effect of High-Speed Sintering and Specimen Thickness on the Properties of 5 mol% Yttria-Stabilized Dental Zirconia Sintered Bodies. Materials (Basel). 2022;15(16):5685.

[https://doi.org/10.3390/ma15165685]

-

Vila-Nova TEL, Gurgel de Carvalho IH, Moura DMD, Batista AUD, Zhang Y, Paskocimas CA, et al. Effect of finishing/polishing techniques and low temperature degradation on the surface topography, phase transformation and flexural strength of ultra- translucent ZrO2 ceramic. Dent Mater. 2020;36(4):e126-9.

[https://doi.org/10.1016/j.dental.2020.01.004]

-

Gómez SY, Da Silva AL, Gouvêa D, Castro RHR, Hotza D. Nanocrystalline yttria-doped zirconia sintered by fast firing. Mater Lett. 2016;166(1):196-200.

[https://doi.org/10.1016/j.matlet.2015.12.042]

- International Organization for Standardization. ISO 6872:2015. Dentistry: Ceramic materials. Geneva: ISO; 2015.

-

Kim HK. Effect of a rapid-cooling protocol on the optical and mechanical properties of dental monolithic zirconia containing 3-5 mol% Y2O3. Materials. 2020;13(8):1923-5.

[https://doi.org/10.3390/ma13081923]

-

Aurélio IL, Marchionatti AM, Montagner AF, May LG, Soares FZ. Does air particle abrasion affect the flexural strength and phase transformation of Y-TZP? A systematic review and meta-analysis. Dent Mater. 2016;32(6):827-845.

[https://doi.org/10.1016/j.dental.2016.03.021]

-

Scherrer SS, Denry IL, Wiskott HW. Comparison of three fracture toughness testing techniques using a dental glass and a dental ceramic. Dent Mater. 1998;14(4):246-55.

[https://doi.org/10.1016/S0109-5641(98)00032-3]

-

Raut VS, Glen TS, Rauch HA, Yu HZ, Boles ST. Stress-induced phase transformation in shape memory ceramic nanoparticles. J Appl Phys. 2019;126(21):1-7.

[https://doi.org/10.1063/1.5118818]

- International Organization for Standardization. ISO 13356:2008. Implants for surgery: ceramic materials based on yttria-stabilized tetragonal zirconia (Y-TZP). Geneva: ISO;2008.