Effect of polymerization type and thickness on color stability of resin cements

본 연구는 제논램프를 사용한 가속시효처리를 시행하여, 광중합형, 이중중합형, 자가중합형의 세가지 중합 방식의 레진 시멘트와 50 μm, 100 μm, 200 μm 의 세 가지 두께에서의 레진 시멘트의 색상 변화를 관찰하였다. 색측계를 이용하여 가속시효처리 시행 전, 후 색상지수를 측정한 후 비교한 결과, 모든 시편에서 임상적으로 유의한 변화가 일어나지는 않았다 (ΔE<3.3). 하지만 자가 중합 방식인 C&B cement 시험군이 다른 광중합, 이중중합방식의 레진 시멘트 시험군보다 변색이 약간 더 일어났다. 레진 시멘트의 중합 두께에 따른 비교에서는 100 μm 두께에서보다는 200 μm두께의 시편에서 더 변색이 크게 됨을 알 수 있었다. 50 μm 두께에서의 시편의 변색이 100 μm 두께의 변색에서 보다 더 크게 나타난 것은 하방에 사용된 아세탈 수지의 변색이 얇은 두께의 레진 시멘트를 통해 나타난 것으로 보이고, 100 μm, 200 μm 두께의 시편은 레진 시멘트가 하방의 아세탈 수지의 변색을 어느 정도 마스킹 효과로 가려준 것으로 보인다. 레진 시멘트의 중합방식과 두께에 따른 불투명도(CR) 측정치 비교에서는 레진 시멘트의 두께가 증가함에 따라서 불투명도 증가가 관찰되었으며, 자가중합 방식의 레진 시멘트의 불투명도 측정치가 조금 크게 관찰되었지만, 시효처리 전, 후 비교에서는 모든 실험군에서 시효처리 후 측정치가 약간 증가하였으나, 중합방식에 따라 특별히 더 많은 불투명도 증가는 관찰되지는 않았다.

Keywords:

Resin cement, Shade, Thickness, AgingINTRODUCTION

Recently laminate veneers have been esthetic treatment for anterior teeth (Rasetto et al., 2001). Resin cements are generally used for the cementation of all-ceramic restorations since they provide adequate aesthetics, low solubility in oral environment, high bond strength to tooth structures, superior mechanical properties (Rosenstiel et al., 2998). These advantages of resin cement can provide more reliable result to patients with esthetic restoration of porcelain laminate veneers. But, resin cements are reported to go through external and internal discoloration (Rosenstiel et al., 2998). The long-term success of porcelain laminates is tied to the color stability of resin cements used.

The color stability and optical properties of resin composites have long been studied (Paravina et al., 2002). Loss of shade match with surrounding tooth structure is a major reason for replacement of esthetic restorations (Kim and Lee, 2007).

The color stability of composite resins had been studied by artificial accelerated aging in different conditions and for different durations (Lee and Power, 2001). Additionally, immersion in different color drinks has been tested (Um and Ruyter, 1991). Discoloration can occur by oxidation and results from water exchange within the polymer matrix and its interaction with unreacted polymer sites and unused initiator or accelerator (Power and Sakaguchi, 2006). Especially internal discoloration has been addressed as a change related to the material’s chemistry such as formation of oxygen byproducts. In chemically activated systems such as dual cure and auto cure resin cement, the oxidation of reactive groups on amine accelerators and inhibitors may cause a color change (Eliades et al., 2004). The accelerators are present in light-cure systems to a much lesser degree as well (Buchalla et al., 2002). Decomposition of inhibitors was found to cause a change in hue towards more yellow (Buchalla et al., 2002).

Hekimoglu et al. (2000) investigated the effects of accelerating aging on an auto-polymerized glass cement (Dyrect Cem) and light- and dual- polymerized resin cements (Enforce and Twinlook). They found the color stability to be acceptable, however, changes in the color stability of newer resin materials were not clarified. The results of studies on the color assessment of self-, light-, dual-polymerizable resin cements are conflicting.

The aim of this in vitro study was to evaluate the change in optical properties of four resin cements that were different in polymerization type, with three different film thickness after subjecting them to accelerated aging.

MATERIALS AND METHODS

Specimen design and cementation procedure

The factors under study were four resin cements, and three film thickness (50, 100, and 200 μm). The association between resin cement and film thicknesses resulted in twelve groups. The experimental samples consisted of 60 specimens (n=5), made in random sequence.

In the current experimental in vitro study, the color parameters of four resin cement (A3 Shade) were evaluated. Table 1 shows the characteristics of the tested cements. Sixty glass slabs (1mm thickness and 25mm x 10mm) were prepared to simulate veneers. The glass slabs were divided into twelve groups of 10 specimens. In each group, one of cements was applied according to the manufacturer’s instructions.

Based on the ISO standards for determination of color stability, materials need to be evaluated in a white background (ISO 7491). White colored and durable acetal polyoxymethylene (Derlin) material was chosen as the background. The dimension of background material were 3 mm x 25 mm x 10 mm. Each Delrin material was labeled from their periphery using a diamond bur and then was ultrasonically cleaned for 10 minutes to eliminate any contamination.

Two strips (positioned at opposite sides of each glass slab) of the 50μm thickness were used as spacer to control the cement film thickness. The three cement films selected for this study were 50, 100, and 200 μ m. Before cementation, the background materials (Derlin) were etched for 15 seconds with 35% phosphoric acid (3M ESPE), washed for 30seconds and dried with air. Next the Single-Bond2 (3M ESPE) adhesive system was applied to the surface and polymerized for 10 seconds (Elipar TriLight, 3M ESPE, standard mode). The gaps between the glass slab and white background were filled with the resin luting cement mixed according to the manufacturer’s instructions. Hand pressure was applied to the glass slabs during polymerization. Each specimen was stored in deionized water at 37˚C for 24 hours prior to testing, to allow any immediate post-cure polymerization of the luting agent to occur.

Colormeter

A color meter (Colormeter ZE 2000, Nippon Denshoku, Japan) was used in this experiment, since the Colormeter is a reference color measuring instrument By using the internal software of the measurement system, color values on the L*, a,* b* color coordinate system were evaluated based upon the measured diffuse reflectance data, used to determine color parameters.. Evaluation of the baseline color properties was done on a black and white background. L*,a*,b* were recorded when the baseline color properties were evaluated. The total color difference between two objects is calculated as ΔE = (ΔL*2+Δa*2+Δb*2)½, where L* stands for lightness, a* represents green-red (-a=green, +a=red) and b* denotes blue-yellow (-b= blue, +b= yellow). The saturation (C) enables the differentiation of pale and strong colors and hue (H) distinguishes the differentiation of color families, for example, red, green, blue. A positive ΔL* indicates that the specimens become darker. And a positive ΔC indicates greater saturation and a negative ΔC indicates less saturation. Since the hue angle (h) of the specimens tested was about 90˚, represents yellow, a positive hue indicated that the color became greener and a negative hue indicated that the color became red. Opacity/ translucency was assessed by obtaining the contrast ratio (CR) of the lightness or Y value of the specimens against both black (Yb) and white (Yw) background, with CR= Yb/Yw2. The pre-weathering color coordinates of each specimens are represented by L*1,a*1,b*1 and post-weathering coordinates are represented by L*2,a*2,b*2.

Parameter equations are as follows:

Accelerated aging

After the initial color measurements, the samples were subjected to accelerated aging procedure (weathering) using xenon light according to ISO standards (4892-2). The accelerating procedure were performed by Ci4000 xenon weather-o-metre (Atlas Electronic Devices Co, Chicago, IL), it was used to apply 0.55 W/m2/nm of xenon light filtered through borate borosilicate glass at 340 nm.

Statistical analysis

One-way ANOVA was used to compare the groups. The paired t-test was used to compare the color parameters in each group before and after aging. All the statistical analysis of the data was performed using SPSS 13.0 for Windows (SPSS Inc, Chicago, IL, USA).

RESULTS

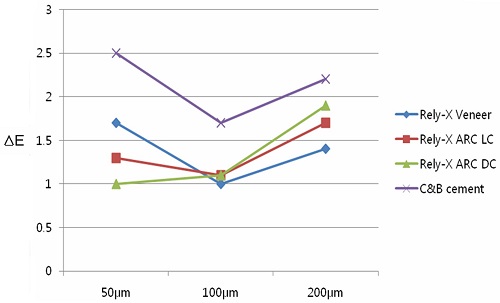

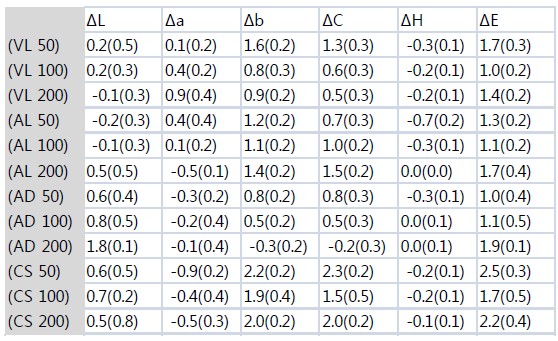

Means and standard deviations of the changes observed in the color parameters of each group are summarized in Table 2. As a result of the accelerated aging procedure, all groups did not go through visible discoloration (ΔE<3). However the color changes of C&B cement groups were higher than other resin cement groups. In other words, self-cure type resin cement discolored more than other light- and dualcure type resin cement.

The color change according to film thickness of resin cement, the color change of 100 μm thickness groups were lower than other 200 μm film thickness groups). That revealed that if film thickness of resin cement were thin, the color changes of resin cement would be less. Color changes (ΔE) were displayed for visual clarification (Table 2).

However the color change of 50 μm thickness groups revealed more color change than 100 μm thickness groups. That would be because of the color change of background material (Derlin). The color changes(ΔE) of the background material (Derlin) was recorded as there was some color change (ΔE>3.3) and the glass slabs were also recorded and found to be unnoticeable (ΔE<1), the thin 50 μm thickness groups would not mask the color change of background materials than other 100 μm, 200 μm thickness groups (Figure 1).

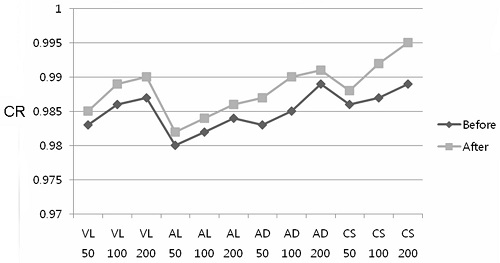

There is some difference in contrast ratio (CR) of the specimens (Figure 2). When the thickness of resin cement increased, the value of CR also increased. This revealed thick film thickness could mask the discoloration of background material (Derlin). After aging the contrast ratio (CR) was slightly higher than that of before aging. It revealed that after aging, the resin materials changed more opaque.

DISCUSSION

Adhesive resin cements, as the generally used luting agent for aesthetics all–ceramic restorations come in various polymerization types and brands. This study evaluated different light-, dual- and self-cure resin cements and different film thickness of 50, 100, and 200 μm in terms of internal color stability. The focus was on the color change according to film thickness and according to polymerization type of resin cement. Although dual- and self- cure resin cement were expected to be more discolored than light-cure resin cement but in thin film thickness, there was no significant difference in color change between lightand dual- cure resin cements. However the color changes of C&B cement groups (self-cure) were higher than other resin cement groups. In other words, self-cure type resin cement discolored more than other light-, dual- cure type resin cement.

Accelerated aging in the xenon light chamber has become a method of simulation of oral conditions for a relatively long service time. Ultraviolet light, temperature and humidity are known to cause oxidation of the amine (Rasetto et al., 2001; Lu and Powers, 2004), which is necessary for initiating the polymerization process. And the aromatic tertiary amines are more contained in the self-cure resins; therefore, light cure cements are expected to have more color stability.

In this study, when using the CIELab color space as the system of color assessment, the ΔE of the cements (whether light-, self- or dual-activated) were not different. While some researchers agree that a ΔE ranging between 2.2 and 4.4 can be considered clinically acceptable, others believe it should be < 3.3 (Lu and Powers, 2004; Hekimoglu et al., 2000). The ΔE calculated for the studied cements in this study was acceptable (less than 3.3).

The samples were stored in water due to the difficulty in adaptation of dietry, habitual and salivary variations of human subjects (Choi et al., 2005). Color stability of the resin materials also need to be evaluated under xenon light.21 Many color studies have used accelerated ageing procedures combining the xenon light exposure with cycles of humidity and light in order to better simulate the oral environment (Hekimoglu et al., 2000). Accelerated ageing protocol however still cannot reliably simulate the clinical situation (Kilinc et al., 2011). Even though it is considered as a harsh environment for its testing conditions, it also serves as a low threshold for material safety determination considering the exclusion of external factors such as absorption of dietary colorants and plaque accumulation (Kilinc et al., 2011).

Rely-X Veneer cement groups were recommended mostly for anterior restorations due to better color stability. And C&B cements were expected to have more color change. In this study, Rely-X Veneer groups were more color stable than C&B cement groups. But, there was no difference with Rely-X ARC groups. And also Rely-X ARC light cure groups and dual cure groups.

According to the results of this study, none of the groups showed a visible color change. On the other hand, the highest color change recorded was a ΔE value of 2.50. This amount is slightly under this study’s acceptable level of a noticeable color change (ΔE < 3.3)

Apart from ΔE, another important factor among the optical properties of esthetic restorations is the covering factor (Kilinc et al., 2011), or opacity. Opacity, on one hand, can give the cement the ability to cover underlying tooth discolorations, while it may render the restoration less lively. After aging, the cements showed a different behavior with regard to their covering ability. C&B cement showed more opacity than the other groups. The exact reason for the change in contrast ratio and the different behavior of the various cements still needs to be studied; however, it is believed that stress cracks within the polymer matrix and partial debonding of the filler from the resin as a result of hydrolysis, may increase opacity and alter the appearance (Power and Sakaguchi, 2006).3 In this study, all of the groups became more opaque.

Lee at al (2001) indicated that commercial composites, claiming to have similar Vita shades, have significant color difference and different opacity levels. The opacity of resin cements is as important as the hue. Accelerated aging may have caused some degradation of the resin cements, and the opacity observed may have resulted from this disintegration.

In this study the background material (Derlin) was used to replace tooth materials. And glass slide was used to replace porcelain laminate veneers. Kilinc et al. (2011) reported there is no significant color change of Derlin during accelerated aging. The color changes (ΔE) of the background material was recorded as there was some color change (ΔE>3.3) and the glass slabs were also recorded and found to be unnoticeable (ΔE<1). These color change of background materials might affect 50 μm thickness groups, it revealed more color change than 100 μm thickness groups. Thin 50 μm thickness groups could not mask the color change of the background material effectively.

CONCLUSIONS

The purpose of this study was to evaluate the effect of film thickness and polymerization type of resin cement to color change of resin cement.

1. Color change of resin luting cements according to polymerization type were unnoticeable (ΔE<3.3), but self-cure type had shown more color change.

2. Color change of resin luting cements according to film thickness has shown some difference. In a film thickness of 100 μm, color changes of all four resin cements were less than thickness of 200 μm.

3. The contrast ratio (CR) was slightly increased after aging process. And also slightly increase according to increase of film thickness.

Light-cure type resin cements were recommended for anterior restorations due to better color stability compare to dual- and self-cure resin cements. But clinically thin film thickness like 50 μm, 100μm, there was no statistical difference between light-cure type and dual-cure type resin cements but self-cure type resin cements were shown more color change than other types of polymerization cements.

Acknowledgments

This research was supported by Kyungpook National University Research Fund, 2013.

References

-

SF Rosenstiel, MF Land, BJ Crispin, Dental luting agent: a review of the current literature, J Prosth Dent, (1998), 80, p280-301.

[https://doi.org/10.1016/S0022-3913(98)70128-3]

-

LJ Kim, YK Lee, Changes in color and color parameters of dental resin composites after polymerization, J Biomed Mater Res B Appl Biomater, (2007), 80, p541-546.

[https://doi.org/10.1002/jbm.b.30628]

- JM Power, RL Sakaguchi, Craig’s Restorative Dental Materials 12th ed, Mosby, St. Lous, (2006), p198-199.

- T Eliades, C Gioka, M Heim, G Eliades, M Makou, Color stability of orthodontic adhesive resins, Angle Orthod, (2004), 74, p391-393.

-

FH Rasetto, CF Driscoll, JA von Fraunhofer, Effect of light source and time on the polymerization of resin cement through ceramic veneers, J Prosthodont, (2001), 10, p133-139.

[https://doi.org/10.1111/j.1532-849X.2001.00133.x]

- H Lu, JM Powers, Color stability of resin cements after accelerated aging, Am J Dent, (2004), 17, p354-358.

- CM Um, IE Ruyter, Staining of resin based veneering materials with coffee and tea Quintessence Int, (1991), 22, p377-386.

- C Hekimoglu, N Anil, I Etikan, Effect of accelerated aging on the color stability of cemented laminate veneers, Int J Prosthodont, (2000), 13, p29-33.

-

W Buchalla, T Attin, RD Hilgers, E Hellwing, The effect of water storage and light exposure on the color and translucency of a hybrid and a microfilled composite, J Prosthet Dent, (2002), 87, p264-270.

[https://doi.org/10.1067/mpr.2002.121743]

- RD Paravina, JC Ontiveros, JM Powers, Curingdependent changes in color and translucency parameter of composite bleach shades, J Esthe Restor Dent, (2002), 14, p158-166.

- YK Lee, JM Power, Color and potical properties of resin-based composites for bleached teeth after polymerization and accelerated aging, Am J Dent, (2001), 14, p349-354.

-

E Kilinc, SA Antonson, PC Hardigan, A Kesercioglu, Resin cement color stability and its influence on the final shade of all-ceramics, J Dent, (2011), 39(Suppl 1), pe30-36.

[https://doi.org/10.1016/j.jdent.2011.01.005]

-

MS Choi, YK Lee, BS Lim, SH Rhee, HC Yang, Changes in surface characteristics of dental resin composites after polishing, J Mater Sci Mater Med, (2005), 16, p347-353.

[https://doi.org/10.1007/s10856-005-0634-9]